- Battery Smart Factory Solution

- EV Smart Factory Solution

- ESS Smart Factory Solution

- Laser Applying Solution

- Smart Warehouse Solution

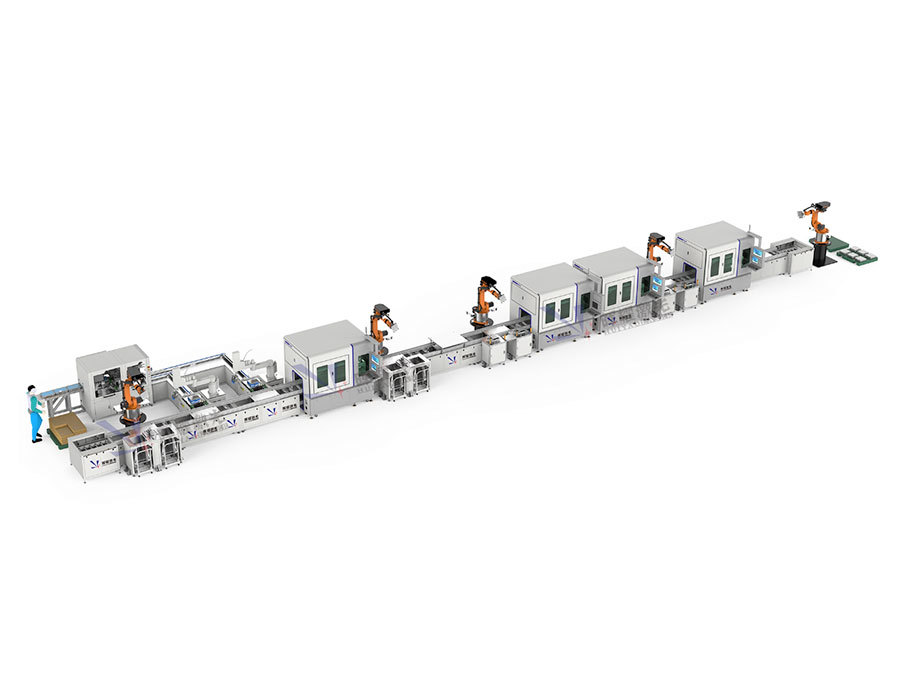

- Prismatic Battery Manufacture Line

- Prismatic Battery Cap Manufacture Line

- Cylindrical Battery Manufacture Line

- EV Prismatic Battery Module PACK Assembly Line

- EV Cylindrical Battery Module PACK Assembly Line

- EV Pouch Battery Module PACK Line

- EV Blade Battery Module PACK Line

- EV Prismatic Battery CTP Automatic Welding Line

- EV Blade Battery CTP Automatic Welding Line

- Robot Laser Welding Workstation

- Battery Cell Module PACK Testing Equipment

- MES Solutionfor EV Smart Factory

Battery Smart Factory Solution

Scheme Introduction

Related products

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Battery Blue Film Wrapping Equipment

Blue protective insulation film is automatically wrapped around the battery cell to enhance electrical insulation and surface protection.

Cylindrical Battery Manufacture Line

Automatic feeding and alignment of electrode and separator materials for cell winding.

Impedance Performance Testing Station

Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.

Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.

Cover Plate Assembly Welding Station

Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.

Explosion-Proof Valve Welding Station

Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.

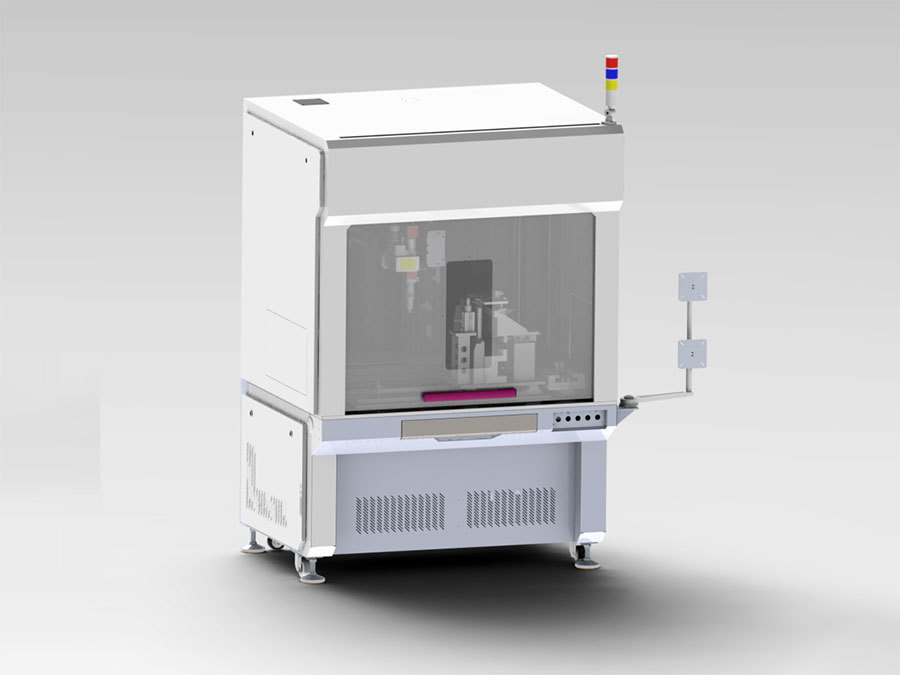

Dual-Station Enclosed Rotary Welding Machine

Precision welding of battery components, metal parts, or other materials requiring high-speed, dual-station rotary processing. The enclosed design ensures operator safety and minimizes environmental interference.

Automatic Explosion-Proof Valve Welding Machine

Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards.

Six-Station Rotary Welding Machine

Designed for efficient, high-precision welding of battery components or metal parts in a continuous rotary process, combining multiple welding operations into a single machine.

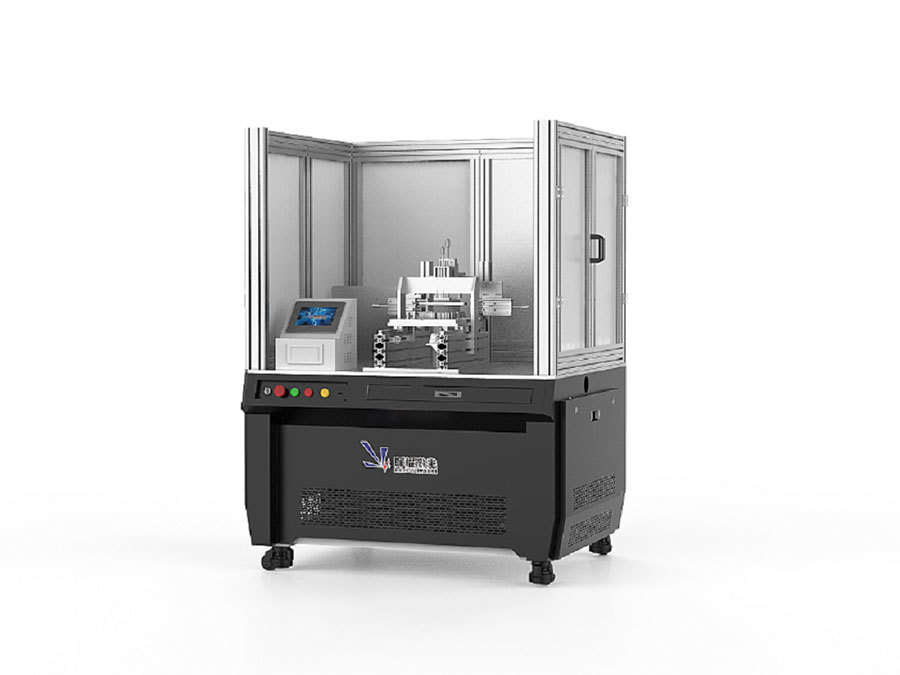

Dual-Station Terminal Pole Welding Machine

High-speed and precise welding of terminal poles for prismatic, cylindrical, and pouch battery cells. The dual-station design ensures continuous operation, improving efficiency and reducing downtime.

Battery Sealing Pin Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Prismatic Battery Helium Leak Detection Equipment

Precision helium leak detection for prismatic, cylindrical, and pouch battery cells to ensure airtight sealing and safety compliance in battery manufacturing processes.

Battery Case Insertion and Top Cap Pre-Welding Equipment

Automated insertion of battery cells into protective cases and precise pre-welding of top caps to ensure structural integrity before final welding. Suitable for prismatic and pouch batteries.

Battery Mylar Film Wrapping Equipment

Precise wrapping of Mylar insulation film around battery cells for enhanced safety and electrical isolation in prismatic, cylindrical, and pouch batteries.

Battery Terminal Tab Transition Sheet Welding Equipment

Specialized for high-precision welding of battery terminal tabs to transition sheets in lithium-ion battery manufacturing. Supports multi-layer material welding with consistent bonding quality.

Battery Terminal Tab Ultrasonic Welding Equipment

Precise ultrasonic welding for battery terminal tabs, suitable for prismatic, cylindrical, and pouch cell configurations.

Precise hot pressing and lamination of prismatic lithium-ion battery cells during assembly processes.

Battery Terminal Tab Welding Equipment

High-precision welding of battery terminal tabs for prismatic, pouch, and cylindrical batteries. Designed for a variety of tab materials including aluminum, nickel, and copper.

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6