Solution

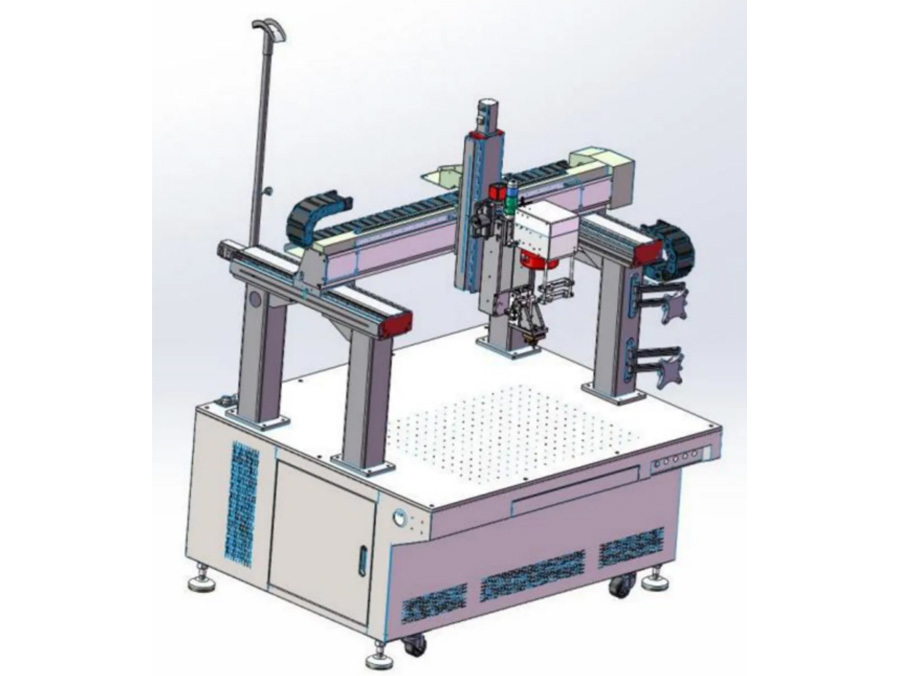

Battery Terminal Tab Welding Equipment

- Product description

-

- Commodity name: Battery Terminal Tab Welding Equipment

- Commodity ID: 电池极耳焊接设备

High-precision welding of battery terminal tabs for prismatic, pouch, and cylindrical batteries. Designed for a variety of tab materials including aluminum, nickel, and copper.

1. Equipment Overview

- Equipment Name: Battery Terminal Tab Welding Equipment

- Model: HY-TTW4040

- Application: High-precision welding of battery terminal tabs for prismatic, pouch, and cylindrical batteries. Designed for a variety of tab materials including aluminum, nickel, and copper.

2. Mechanical Specifications

- Equipment Dimensions:

- Length: 2000 mm

- Width: 1800 mm

- Height: 2100 mm

- Weight: 1300 kg ± 5%

- Frame Material: High-strength steel frame with powder coating for durability.

- Worktable: Hardened stainless steel with anti-static surface treatment.

- Motion System: Servo motor-driven X-Y-Z axes with linear guide rails for high precision.

3. Welding Specifications

- Welding Technology:

- Standard: Laser welding.

- Welding Power: 2-6KW, depending on pole thickness and material.

- Welding Speed: 5–10 welds per minute (process-dependent).

- Welding Accuracy: ±0.1 mm.

- Tab Thickness Range: 0.1–0.5 mm.

- Tab Material Compatibility: Aluminum, copper, nickel, and multi-layer laminates.

4. Vision and Positioning System

- Camera Specifications:

- Type: High-resolution CCD camera with auto-focus capability.

- Resolution: 5 MP.

- Alignment Accuracy: ±0.05 mm using image recognition algorithms.

- Lighting: Adjustable LED ring light for consistent illumination.

- Detection Features:

- Pre-weld alignment verification.

- Post-weld inspection for defects such as cracks or misalignment.

5. Control and Interface

- Control System: Based on welding control card with integrated HMI (Human-Machine Interface).

- Display: 19-inch touchscreen with intuitive UI.

- Programmable Features:

- Welding parameters (power, duration, pressure).

- Alignment and positioning adjustments.

- Recipe storage for different battery types.

- Data Logging:

- Internal storage: 1 TB SSD.

- Export Formats: CSV and PDF via USB, Ethernet, or Wi-Fi.

6. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 36 kW.

- Control Voltage: 24V DC for internal systems.

7. Safety Features

- Emergency Stop: Multiple emergency stop buttons strategically placed.

- Overload Protection: Real-time current and force monitoring with automatic system shutdown.

- Safety Enclosure: Transparent safety covers with interlocks to prevent operation when open.

8. Environment & Installation

- Operating Environment:

- Temperature: 10–30°C

- Humidity: ≤60% RH (non-condensing).

- Noise Level: ≤75 dB during operation.

- Installation Requirements:

- Flat surface with anti-vibration foundation.

- Clearance: Minimum 800 mm on all sides.

9. Optional Configurations

- Dual Welding Heads: For simultaneous processing of multiple tabs.

- IoT Connectivity: Real-time process monitoring and predictive maintenance.

10. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Clean welding head and lens.

- Monthly: Inspect and calibrate alignment systems.

- Quarterly: Lubricate moving parts and check electrical connections.

- Warranty Period:

- Standard: 12 months.

- Extended: Up to 36 months upon request.

Key words:

Battery Terminal Tab Welding Equipment

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

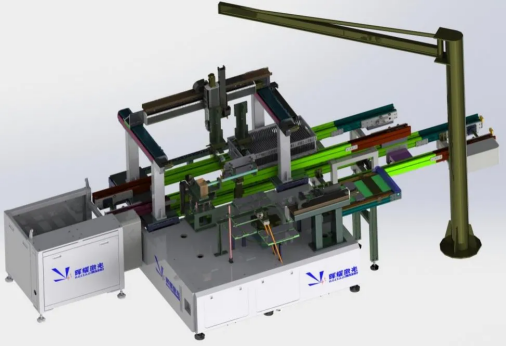

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6