Solution

Prismatic Battery Module Line

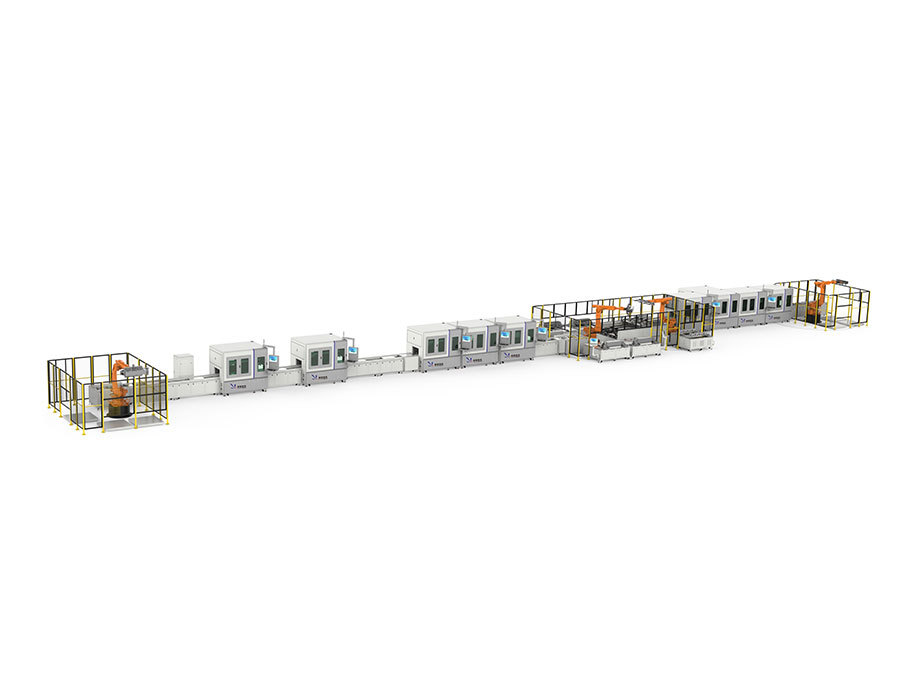

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

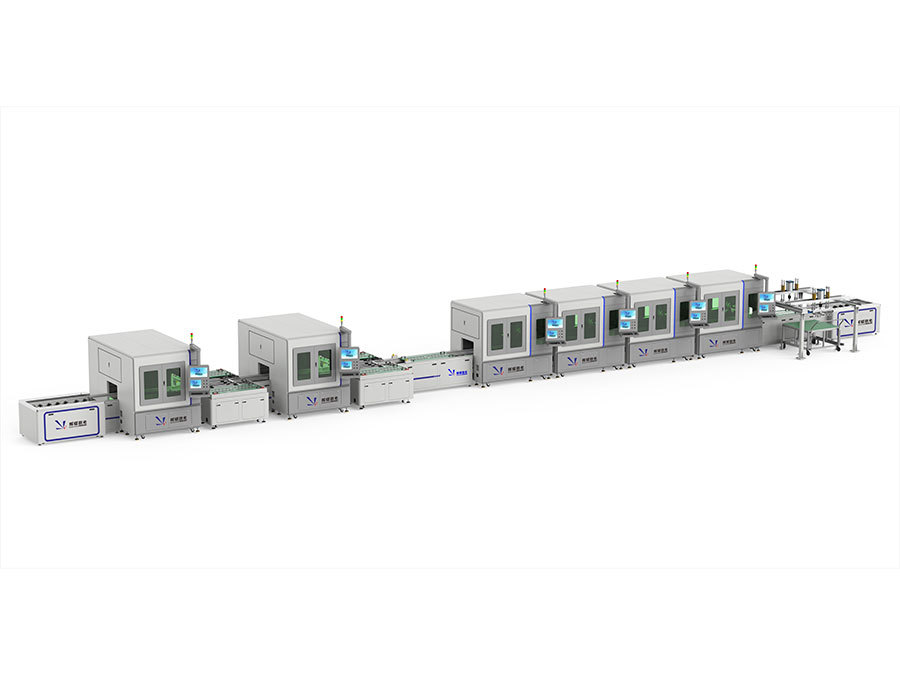

Huiyao Laser Semi-Automated Energy Storage Prismatic Battery Module PACK Line

The Huiyao Laser Energy Storage Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

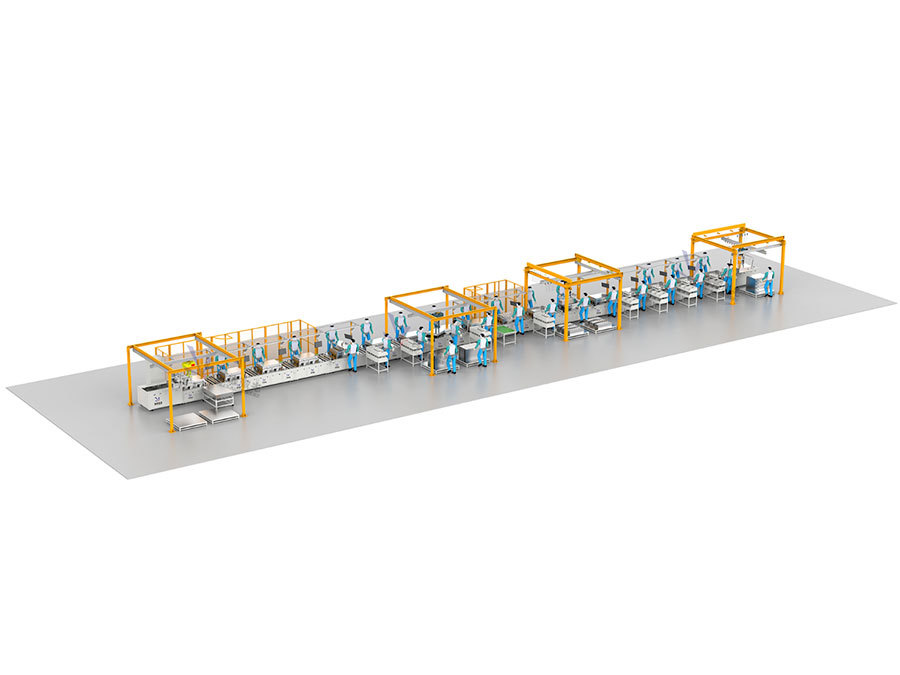

ESS Prismatic Battery Module PACK Assembly Line

The ESS Prismatic Battery Module PACK Assembly Line is engineered to deliver high-precision, high-throughput manufacturing of energy storage system (ESS) prismatic battery packs.

EV Prismatic Battery CTP Automatic Welding Line

The EV Prismatic Battery CTP (Cell-to-Pack) Automatic Welding Line is a high-performance.

EV Prismatic Battery Module PACK Assembly Line

Automatic sorting of battery cells based on voltage, capacity, and internal resistance.

Prismatic Battery Cap Manufacture Line

Fully automated production line for prismatic battery cells, integrating critical processes such as explosion-proof valve welding, cover plate assembly welding, air-tightness testing, and impedance/performance testing.