Solution

ESS Prismatic Battery Module PACK Assembly Line

- Product description

-

- Commodity name: ESS Prismatic Battery Module PACK Assembly Line

- Commodity ID: 储能方壳电池模组PACK线

The ESS Prismatic Battery Module PACK Assembly Line is engineered to deliver high-precision, high-throughput manufacturing of energy storage system (ESS) prismatic battery packs.

1. Technical Introduction: ESS Prismatic Battery Module PACK Assembly Line

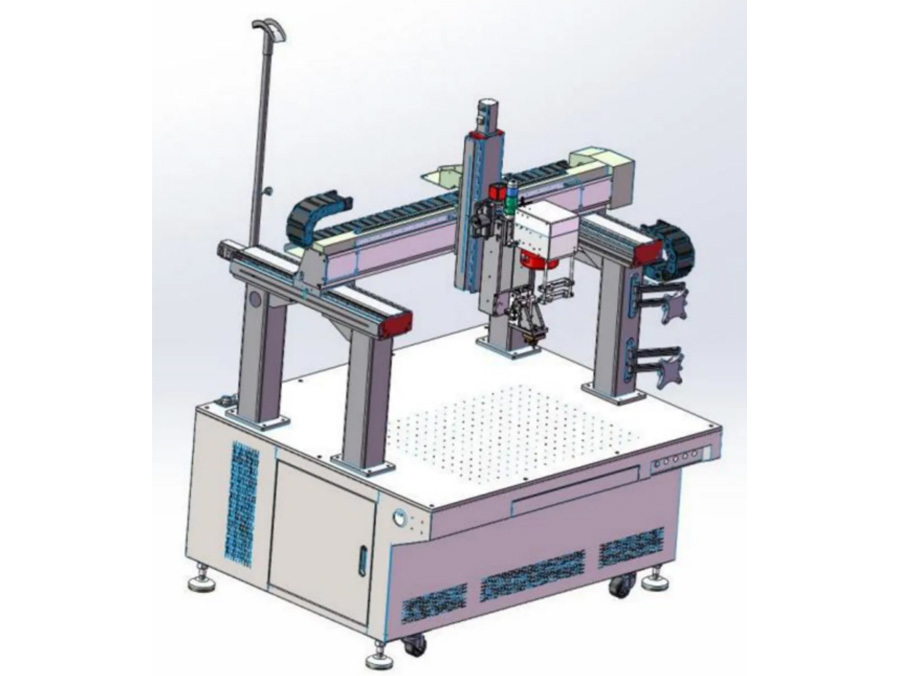

Engineered for the rigorous demands of Utility-scale and C&I Energy Storage projects, this fully automated assembly line is optimized for large-format 280Ah and 314Ah Prismatic LFP cells.

Unlike semi-auto lines that suffer from inconsistent quality, our turnkey solution integrates high-speed OCV sorting, 6-axis robotic stacking, and fiber laser welding into a seamless workflow. Designed to deliver a cycle time of 15 PPM with >95% OEE, this line empowers manufacturers to eliminate manual errors and achieve automotive-grade precision with full MES digital traceability.Fully compatible with VDA 390 / 590 modules. Designed for Gigafactory scalability (from pilot run to 1.25 GWh+ mass production).

2. Process Flow and Technical Overview:

2.1 Thermal Interface Material (TIM) Insertion

- Process: Automated dispensing systems insert a consistent layer of TIM at the bottom of the prismatic battery box.

- Technical Detail:The TIM is precisely dispensed to ensure uniform thickness and full coverage, ensuring optimal heat dissipation between the prismatic cells and the battery housing. This is critical for maintaining battery performance and longevity under load conditions.

2.2 Module Insertion and Alignment

- Process: High-precision handling systems load prismatic battery modules into the battery box, ensuring proper orientation and mechanical alignment.

- Technical Detail:Automated feeders, combined with vision systems, ensure that each module is aligned to within ±0.1mm accuracy to avoid misalignment issues during assembly. The modules are secured within the box using automated pressing mechanisms to ensure even distribution of mechanical forces.

2.3 Glue Application for Top Cover Assembly

- Process: Precision glue dispensers apply an even layer of adhesive to the top of the battery box for secure attachment of the top cover.

- Technical Detail:The glue dispensing system is calibrated for precise volume control, applying the correct adhesive amount for a uniform bond. This system is integrated with a real-time vision inspection system to verify glue pattern and volume consistency, ensuring a strong bond that adheres to industry standards.

2.4 Top Cover Mounting

- Process: The top cover of the battery box is mounted automatically using robotic arms, followed by fastening using high-torque screwdrivers.

- Technical Detail:Robotic arms (such as KUKA models) are programmed to handle the top cover, aligning it precisely with the battery box using vision-guided systems. Fastening is performed with torque-controlled screwdrivers to ensure consistent sealing pressure and to prevent over-tightening or under-tightening, which could compromise pack integrity.

2.5 End-of-Line (EOL) Testing

- Process: Once the module is assembled, it undergoes a series of automated tests at the EOL station.

- Technical Detail:The EOL testing station is equipped with electrical testing units that check key parameters such as voltage, capacity, impedance, and thermal behavior. Advanced diagnostic equipment performs high-voltage insulation resistance tests, overcharge/discharge simulations, and short-circuit fault injections to ensure that each module adheres to strict performance and safety standards. These tests ensure compliance with UL, IEC, and other international safety certifications.

2.6 Labeling and Custom Branding

- Process: The final step involves labeling the completed battery pack with customer-specific branding and serial numbers.

- Technical Detail:A fully automated labeling system uses high-precision printers and robotic placement arms to apply labels accurately and securely. The label includes critical information, such as battery specifications, date codes, and safety warnings, as required for traceability and compliance purposes.

3. Automation, Robotics, and Quality Control Systems:

- Robotic Arms and Automated Handling Systems:

- The line utilizes a series of KUKA robotic arms, equipped with advanced vision systems and end-of-arm tooling (EOAT), for tasks including module handling, glue application, top cover assembly, and pack transfer. The robotic arms are configured for high payload capacity, speed, and flexibility, with precision repeatability of ±0.05mm to ensure optimal alignment and assembly.

- Vision Inspection and Error Detection:

- Integrated vision systems, such as high-resolution cameras and laser sensors, continuously monitor every step of the assembly process. These systems perform real-time quality inspections, verifying module placement, adhesive application, alignment, and torque settings. Any deviations from the predefined tolerances trigger automatic alerts and corrections to maintain production quality.

- Conveyor Systems and Centralized Control:

- The assembly line employs high-speed conveyor systems with modular design for flexible line configuration. A centralized PLC-based control system manages the entire process, ensuring synchronized operation between various stations. Real-time data monitoring and analytics allow for predictive maintenance, minimizing downtime and improving operational efficiency.

4. Technical Advantages:

- High Precision and Repeatability:

- The use of robotics, vision-guided systems, and automated handling ensures that each module and pack assembly is executed with consistent precision, meeting tolerances of up to ±0.1mm in alignment and ±0.5% in component placement.

- Throughput and Scalability:

- The assembly line is designed for high throughput, capable of producing thousands of ESS prismatic battery packs per day. The modular design allows easy scalability for different production volumes, accommodating both small-batch and mass production needs.

- Advanced Safety and Compliance:

- The entire line is built with safety protocols aligned with international standards (e.g., ISO 26262, IEC 61508). This includes automated safety stops, emergency shutoff systems, and real-time monitoring of electrical, mechanical, and environmental parameters to safeguard against potential hazards during the assembly process.

- Flexibility for Custom Configurations:

- The line is highly adaptable, capable of handling multiple prismatic battery sizes and configurations. Whether dealing with different voltages (e.g., 12V, 48V) or customized pack designs, the system can be reconfigured rapidly with minimal downtime.

- Cost Efficiency and Reduced Labor Dependency:

- With a fully automated workflow, labor costs are reduced, and the risk of human error is minimized, ensuring optimal performance and cost-effective production.

5. Conclusion:

The ESS Prismatic Battery Module PACK Assembly Line represents the next generation of automation in energy storage system manufacturing. By integrating advanced robotics, automated quality control, and high-precision assembly techniques, it offers manufacturers a robust, scalable solution for producing high-quality prismatic battery packs with reduced cycle times, enhanced safety, and compliance with international standards. This assembly line supports the growing demand for reliable, efficient energy storage solutions across a variety of industries, including renewable energy, electric vehicles, and grid stabilization.Experiencing welding defects? Read our Troubleshooting Guide

6. Technical Specifications

Technical Parameter Specification Engineering Value Cycle Time (Efficiency) 8 PPM-15 PPM (Pieces Per Minute) Validated for high-volume grid storage projects. Laser Welding Power 6000W (6kW) Fiber Laser Ensures deep penetration for busbar durability. Max Payload Capacity 500 kg Engineered for heavy-duty ESS battery modules. Data Traceability Full MES Integration 100% digital birth certificate for every pack. Qualification Rate ≥ 99.8% Automotive-grade consistency for energy storage. 7. Why Huiyao Offers the Best Prismatic Assembly Line?

Why We Choose Fiber Laser Over Ultrasonic for ESS?

For large-format Prismatic cells (280Ah/314Ah), traditional Ultrasonic Wedge Bonding often lacks the power to penetrate thick busbars. We utilize Fiber Laser Welding to ensure a structural fusion bond.

Engineering Metric Huiyao Fiber Laser Welding Traditional Ultrasonic Bonding Bond Type Deep Fusion Keyhole (Metallurgical bond) Surface Friction Bond Penetration Depth > 2.5 mm (Adjustable) < 0.5 mm (Surface only) Clamping Force Zero (Non-contact) High Pressure (Risk of terminal deformation) Electrical Resistance Ultra-Low (< 5μΩ) Low (< 10μΩ) Suitability Best for Prismatic / Cylindrical Best for Pouch Cell Tabs Engineering Note:

Planning a Pouch Cell line? Laser welding is generally NOT recommended for soft pouch tabs due to heat sensitivity. Please visit our [Pouch Battery Assembly Line] page for Ultrasonic solutions.

Need a welding proof? Send us your busbar and terminal samples.8. Custom Battery Pack Assembly & Layout Design

Every factory is unique. Huiyao provides fully custom battery pack assembly solutions tailored to your specific prismatic cell dimensions (VDA, MEB, or custom sizes).

Flexible Layouts: We design Straight, L-shape, or U-shape lines to fit your existing floor plan.

Scalable Automation: Choose from Semi-Auto (for pilot lines) to Fully Automated (for mass production) configurations based on your budget.

Format Changeover: Modular tooling design allows for quick changeovers between different battery models in under 30 minutes.

Q4: What are the facility requirements for installing this line?

A: To run the ESS Assembly Line at full speed (15 PPM), we recommend the following facility conditions:

Clear Height: Minimum 4.5 meters for gantry robots and dust collection pipes. (Low-profile custom designs available for 3.5m ceilings).

Floor Loading: Concrete floor capable of supporting > 800 kg/m², especially in the stacking and welding zones.

Environment: ISO Class 8 (100,000) Cleanroom is recommended for the welding section to prevent contamination.

Q5: Is this line compatible with Sodium-ion (Na-ion) or Solid-state batteries?

A: Yes. As long as the cell format remains Prismatic (Hard Case), our handling and stacking mechanisms are 100% compatible.

For Sodium-ion, the process is identical to LFP.

For Solid-state, we may need to adjust the stacking pressure parameters, which is easily done via our MES Recipe Management.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A