Product

Stacking and Pressing Machine

- Product description

-

- Commodity name: Stacking and Pressing Machine

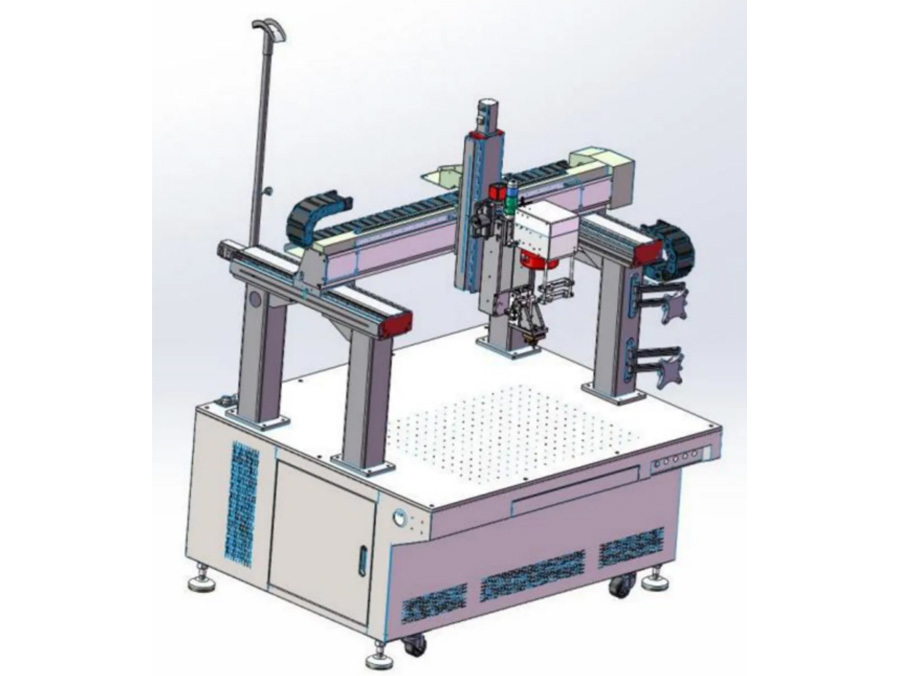

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Equipment Overview

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Mechanical Specifications

● Compatible Cells: 280Ah, 314Ah (and other specifications, customization supported)

● Module Configuration: Supports 1P8S to 1P16S (customizable)

● Core Structure: Robust steel frame, top plate assembly, module backstop assembly, and tray slide rail assembly.

● Loading System: Manual loading via tray slide rail.

Pressing System

● System Type: Fully Pneumatic (Air-powered).

● Actuator: High-thrust pneumatic cylinder.

● Gas Source Requirement: Dry and clean compressed gas.

● Gas Pressure Range: 0.4 - 0.6 MPa.

Process Control System

● Operator Control: Manual valve switch to initiate and retract the pressing cylinder.

● Feedback System: Equipped with a high-precision digital pressure sensor.

● Display: Real-time pressure sensor data is transmitted to an on-board digital display screen, allowing the operator to monitor pressing force.

● Workflow: 1. Operator manually places the module onto the tray and slides it into the pressing station. 2. The module backstop is engaged. 3. Operator presses the manual valve switch to engage the pneumatic cylinder. 4. Operator monitors the digital display to achieve the target pressure. 5. Operator manually locks the module fasteners (e.g., metal plates). 6. Operator retracts the cylinder via the manual valve. 7. Operator removes the backstop, slides the tray back, and unloads the completed module.

Electrical Specifications

(Pertains to the digital pressure sensor and display instrument only)

● Primary Power: AC Power (AC indicator light).

● Backup Power: Built-in rechargeable battery for portable operation.

● Battery Voltage: 4-level power display (6.19V / 5.99V / 5.77V / 5.55V).

● Auto-Off: Instrument automatically powers down when the battery is depleted to protect the battery life.

Safety Features

● Mechanical Safety: Robust steel frame construction.

● Process Safety: Manual module backstop ensures correct positioning before pressing.

● Operator Safety: Manual valve control gives the operator full command over the pressing and retraction process.

Environment & Installation

● Gas Requirement: Must be connected to a dry and clean compressed gas source processor.

● Gas Pressure: 0.4 - 0.6 MPa.

● Grounding: The power supply grounding terminal for the instrument must be reliably grounded.

Optional Configurations

● Custom Fixturing: Trays and pressing fixtures can be customized to support various prismatic cell specifications (e.g., 280Ah, 314Ah, or others) and module configurations (1P8S to 1P16S or custom).

Maintenance and Warranty

● Maintenance: Requires ensuring the compressed gas source remains dry and clean. The instrument's built-in battery should be charged for 10-16 hours regularly, and energized every 2 months if not in long-term use.

● Warranty & Support: We provide free on-site training for customer personnel (engineering, operation, and maintenance) to ensure full understanding of the equipment's working principles, operation, and maintenance procedures.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A