Solution

EV Prismatic Battery Module PACK Assembly Line

- Product description

-

- Commodity name: EV Prismatic Battery Module PACK Assembly Line

- Commodity ID: 动力方壳电池模组PACK线

Automatic sorting of battery cells based on voltage, capacity, and internal resistance.

1. Equipment Overview

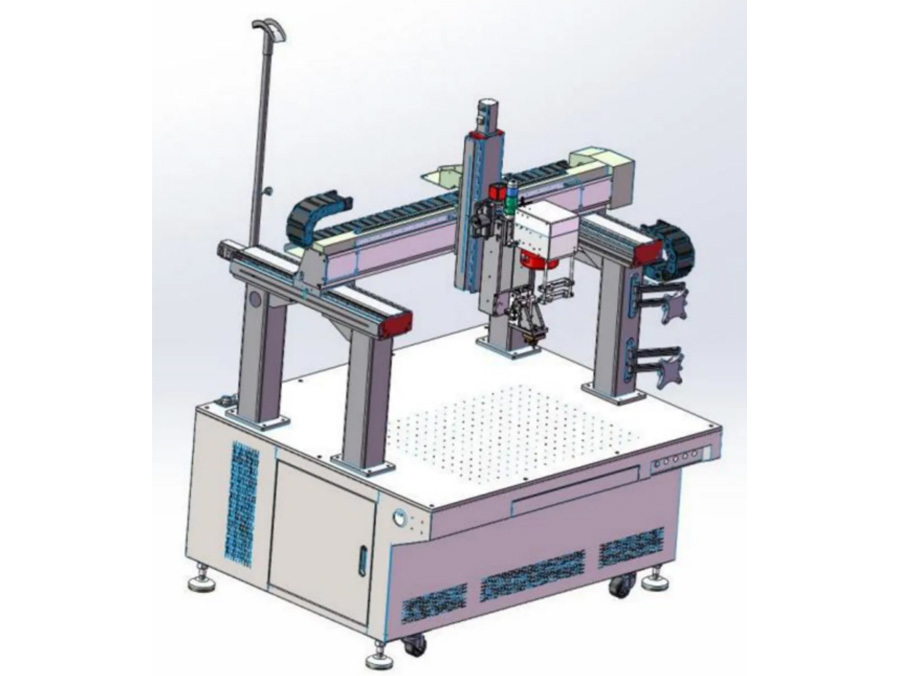

Engineered for the rigorous demands of Tier-1 EV Battery Manufacturers, this fully automated assembly line is compatible with VDA / MEB standard Prismatic cells.

Unlike general-purpose lines, our turnkey solution integrates high-speed OCV sorting, 6-axis robotic stacking, and Busbar Laser Welding into a compliant automotive-grade workflow. Designed for 15 PPM cycle times with >95% OEE, this line supports both Module-to-Pack and CTP (Cell-to-Pack) configurations with full MES digital traceability.

2. Key Processes and Modules

2.1 Battery Cell Sorting Station

- Function: Automatic sorting of battery cells based on voltage, capacity, and internal resistance.

- Specifications:

- Sorting Accuracy: ±0.01% rdg. ±3 dgt (voltage), ±0.5% rdg. ±10 dgt (resistance).

- Throughput: 720 cells/hour.

2.2 Module Frame Assembly

- Function: Automatic assembly of prismatic battery cells into the module frame.

- Specifications:

- Frame Size: Customizable for module dimensions.

- Positioning Accuracy: ±0.1 mm.

- Cycle Time: ≤5 seconds per cell.

2.3 Busbar Welding Station

- Function: Laser welding of busbars to battery terminals for electrical connection.

- Specifications:

- Laser Type: Fiber laser, 3000-4000 W.

- Welding Accuracy: ±0.05 mm.

- Welding Speed: ≤5 seconds per weld.

2.4 Insulation and Protection Assembly

- Function: Placement of insulating materials and protective components to ensure safety.

- Specifications:

- Material Compatibility: Mylar, foam pads, and plastic shields.

- Placement Accuracy: ±0.1 mm.

- Automation Level: Fully automated with robotic handling.

2.5 Module Testing Station

- Function: Electrical and functional testing of assembled modules.

- Specifications:

- Testing Parameters: Voltage, internal resistance, insulation, and thermal performance.

- Testing Speed: ≤30 seconds per module.

- Data Storage: Test results logged for traceability.

2.6 PACK Assembly and Integration

- Function: Assembly of battery modules into the PACK housing, including cooling system and connectors.

- Specifications:

- PACK Size Range:

- Length: 500–1200 mm.

- Width: 400–800 mm.

- Height: 100–300 mm.

- Positioning Accuracy: ±0.2 mm.

- Cycle Time: ≤120 seconds per PACK.

- PACK Size Range:

2.7 Final Testing and Inspection

- Function: Comprehensive testing of the final PACK for performance and safety.

- Specifications:

- Testing Parameters: Voltage, capacity, insulation, short-circuit, and helium leak detection.

- Testing Speed: ≤2 minutes per PACK.

- Quality Criteria: Pass/fail thresholds programmable via software.

3. Production Line Specifications

- Overall Dimensions:

- Length: 50,000 mm.

- Width: 8,000 mm.

- Height: 3,000 mm.

- Weight: Approximately 25,000 kg.

- Production Capacity: Up to 30 PACKs/hour.

- Automation Level: Fully automated with robotic and vision systems.

4. Vision and Quality Inspection Systems

- Alignment Cameras:

- Accuracy: ±0.02 mm for component placement.

- Resolution: 5 MP high-speed cameras.

- Defect Detection: AI-based algorithms for weld quality, misalignment, and surface anomalies.

- Data Logging: All inspection results stored for traceability.

5. Control and Interface

- Control System: Modular PLC with real-time monitoring and control.

- Human-Machine Interface (HMI):

- 10-inch touchscreen with multi-language support.

- Parameter adjustment and process monitoring.

- IoT Connectivity:

- Remote diagnostics, software updates, and production analytics.

6. Safety Features

- Enclosures: Fully enclosed with interlocks for each station.

- Emergency Stops: Strategically placed along the line.

- Welding Safety: Laser enclosures and certified protective glass.

- Electrical Safety: Overload and fault detection systems.

7. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 150 kW.

- Control Voltage: 24V DC for auxiliary systems.

8. Cooling System

- Type: Centralized water cooling for laser systems and high-power electronics.

- Cooling Capacity: 10 kW.

- Flow Rate: 20–40 L/min.

9. Environmental Requirements

- Operating Environment:

- Temperature: 15–30°C.

- Humidity: ≤60% RH (non-condensing).

- Noise Level: ≤75 dB during operation.

- Installation Space: Minimum clearance of 2,000 mm around the line.

10. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspect vision systems, welders, and alignment mechanisms.

- Monthly: Calibration of testing equipment and laser systems.

- Quarterly: Comprehensive diagnostics of all stations.

- Warranty Period:

- Standard: 12 months.

- Extended: Up to 36 months available upon request.

11. Technical Specifications

Technical Parameter

Specification

Engineering Value

Assembly Cycle Time

12 PPM (Modules Per Minute)

High-speed throughput for EV Tier 1 supply chains.

Hipot Test Voltage

5000V (5kV) DC

Verifies insulation integrity to prevent short circuits.

Positioning Accuracy

± 0.1 mm

Vision-guided robotics ensure micron-level precision.

Welding Speed

≤ 200 mm/s

Minimizes heat-affected zone (HAZ) on battery cells.

Safety Architecture

Class 1 Laser Enclosure

100% compliant with industrial laser safety standards.

Why Fiber Laser Welding is Critical for EV Battery Packs?

For automotive EV packs, structural integrity under vibration is non-negotiable. We utilize Fiber Laser Welding (Deep Fusion) over traditional methods.

Performance Metric Huiyao Laser Welding (EV Grade) Ultrasonic / Resistance Welding Bond Strength > 3000N (Deep Fusion) < 1500N (Surface Bond) Penetration Depth > 2.0 mm (Adjustable) Surface Only Vibration Resistance High (Automotive Standard) Risk of fatigue failure Cycle Time < 0.5s / point > 1.5s / point

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A