Solution

Huiyao Laser Semi-Automated Energy Storage Prismatic Battery Module PACK Line

- Product description

-

- Commodity name: Huiyao Laser Semi-Automated Energy Storage Prismatic Battery Module PACK Line

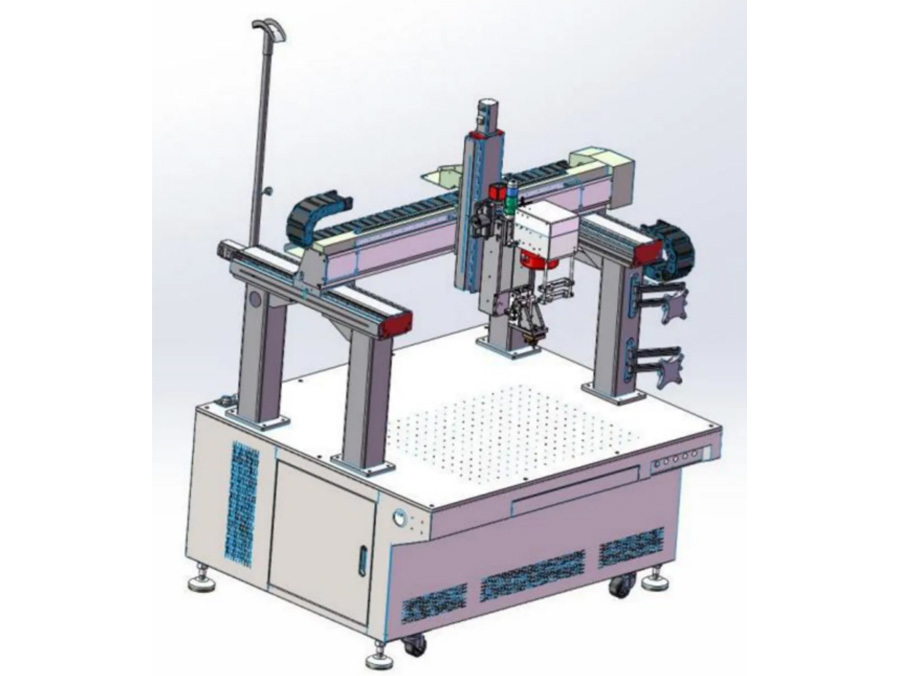

The Huiyao Laser Energy Storage Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

The Huiyao Laser Energy Storage Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

High - precision Laser Welding

Advanced laser welding technology is adopted to ensure high - precision welding between the cell tabs and connection pieces. The welding has high strength and low resistance, significantly improving the electrical performance and safety of the modules.

The welding process is contact - free and pollution - free, suitable for the production of energy storage batteries with high standards.Fully Automated Production

The production line is highly automated, covering processes such as cell feeding, sorting, stacking, welding, encapsulation, detection, and unloading, greatly reducing manual intervention and improving production efficiency.

The automated equipment operates stably and can meet the continuous production demand of 7x24 hours.

Intelligent Detection and Monitoring

Equipped with various detection devices, including voltage detectors, internal resistance testers, insulation withstand voltage testers, etc., to ensure that the electrical performance and safety of each module meet the standards.

The intelligent monitoring system collects production data in real - time, supporting quality traceability and process optimization.Flexible Customized Design

The production line can be flexibly adjusted according to customer needs to adapt to the production of prismatic battery modules of different specifications and models.

The modular design is convenient for upgrading and maintenance, meeting future capacity expansion needs.

High Efficiency, Energy - saving and Environment - friendly

Energy - saving designs and environment - friendly materials are used to reduce energy consumption and environmental pollution.

Processes such as glue coating and welding are in line with green manufacturing standards, helping customers achieve sustainable development.Main Parameters

Production Cycle

≥ 12 PPM (Can be adjusted according to requirements)

Welding Precision

±0.1mm

Detection Items

Voltage, Internal Resistance, Insulation, Withstand Voltage, etc.

Applicable Cell Types

Prismatic Cells (Lithium Iron Phosphate, Nickel - Cobalt - Manganese Lithium, etc.)

Production Line Compatibility

Supports various module sizes and structural designs

Degree of Automation

≥ 95%

Product Process Flow

Main Processes in the Module Section:

Main Processes in the PACK Section

Application Fields

Large - scale Energy Storage Systems: Such as power grid peak regulation, renewable energy energy storage, etc.

Home Energy Storage Systems: Such as household energy storage battery packs.

Industrial Energy Storage Systems: Such as factory backup power supplies, micro - grid systems, etc.

Services and Support

Customized Solution Design: Provide personalized solutions according to customer needs.

Technical Training: Provide customers with comprehensive operation and maintenance training.

After - sales Service: Provide 24 - hour quick - response service to ensure the stable operation of the production line.Main Products

Company Profile

Huiyao Laser Technology (LuoYang) Co., Ltd. (AKA Yao Laser) is an industry-leading manufacturer of new energy intelligent equipment, dedicated to providing innovative turnkey solutions for Battery Module PACK Production Lines and CCS Intelligent Manufacturing Production Line across various industries.

Since its establishment in2019, Yao Laser has continuously advanced the development and application of laser technology, providing customers with high-quality, high-performance laser equipment and Battery Module PACK Automated Production Lines, and CCS Intelligent Manufacturing Production Line.

The company covers an area of 10,800 Square Meters and is equipped with a number of automated and semi-automated production lines and advanced laser welding equipment.Certifications

It holds IS09001 Quality Management System Certification, IS014001Environmental Management System Certification and IS045001 Occupational Health and Safety Management Certification, The company actively promote standardized production models, improves product quality management and ensure after-sales service guarantee, and commits to providing customers with reliable products and high-quality service.

Exhibition&Customers

Our Partners

Since its establishment, Huiyao Laser has established deep cooperation with well-known domestic and international enterprises, such as CALB(China Aviation Lithium Battery), BYD, SVOLT Energy, State Energy Group, Xuji Group, Sacred Sun Power, Tianhui Lithium Battery, New Taihang, Harbin Coslight,and Wan Yang Lithium Battery.

Packaging & Shipping

FAQ

Q1: What is the production cycle of this production line? Can it meet the needs of large - scale production?

A1: The PACK line of Huiyao Laser adopts a highly automated design. The production cycle can reach ≤ 2 minutes per module, and it supports 7x24 - hour continuous operation, fully meeting the needs of large - scale production.

Q2: Does the production line support the production of battery modules of different specifications and models?

A2: Our PACK line adopts a modular design and can be flexibly adjusted according to customer needs. It supports the production of prismatic battery modules of various specifications and models, with strong adaptability.

Q3: How to ensure precision and consistency during the welding process?

A3: The production line uses high - precision laser welding technology, with a welding precision of up to ±0.1mm. At the same time, it is equipped with an intelligent detection system to monitor the welding quality in real - time, ensuring the consistency of each module.

Q4: Is the degree of automation of the production line high enough? Does it require a lot of manual intervention?

A4: The PACK line of Huiyao Laser has a high degree of automation of over 95%, covering processes such as feeding, sorting, stacking, welding, encapsulation, detection, and unloading, greatly reducing manual intervention and improving production efficiency.

Q5: How does the production line ensure that the quality of each module meets the standards?

A5: The production line is equipped with various detection devices, including voltage detectors, internal resistance testers, insulation withstand voltage testers, etc., to ensure that each module meets the standards in terms of electrical performance, insulation, and safety.

Q6: Do the daily maintenance and upkeep of the production line require professional technicians?

A6: Our production line has a simple design and is easy to maintain. At the same time, detailed operation manuals and technical training are provided. In addition, Huiyao Laser also offers a professional after - sales service team to ensure that customers can quickly solve maintenance problems.

Q7: Is the initial investment and long - term operating cost of the production line relatively high?

A7: Although the initial investment is high, the high efficiency and low defect rate of the production line can significantly reduce long - term operating costs. In addition, automated equipment reduces labor costs and material waste, with a high return on investment.

Q8: Can the production line be customized according to our special requirements?

A8: Huiyao Laser provides customized solutions and can adjust the production line design according to the specific needs of customers, ensuring that different specifications, models, and process requirements are met

Q9: Does the production line meet environmental protection requirements?

A9: Our production line uses energy - saving designs and environment - friendly materials to reduce energy consumption and environmental pollution. At the same time, processes such as glue coating and welding are in line with green manufacturing standards.

Q10: If there are problems with the production line, can we quickly get technical support?

A10: Huiyao Laser provides 24 - hour quick - response service and has a professional after - sales service team to ensure that customers have no worries during the production process.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A