Product

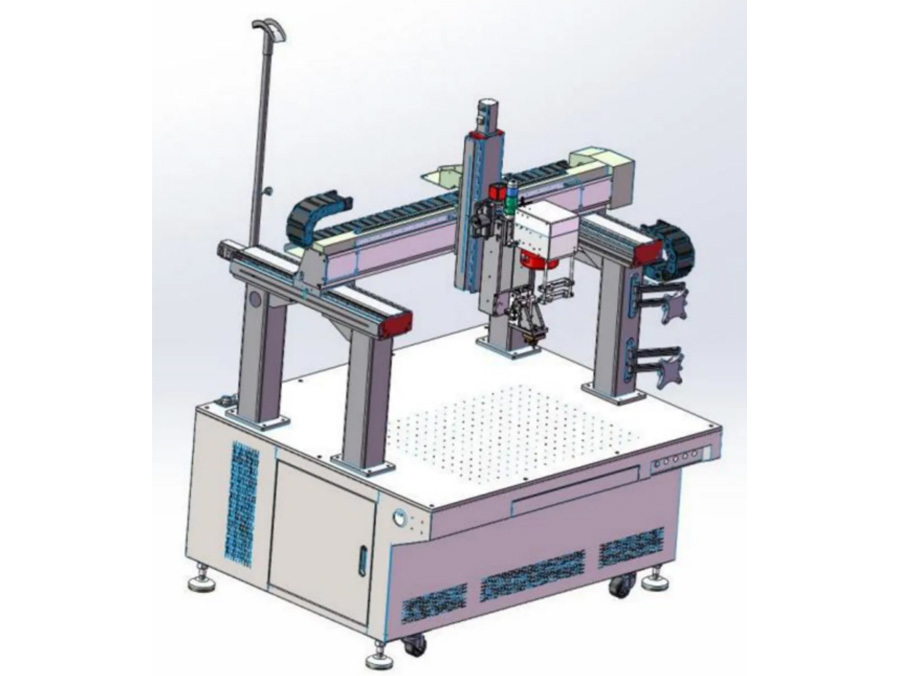

Automatic Explosion-Proof Valve Welding Machine

- Product description

-

- Commodity name: Automatic Explosion-Proof Valve Welding Machine

- Commodity ID: 防爆阀自动焊接机

Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards.

1. Equipment Overview

- Equipment Name: Automatic Explosion-Proof Valve Welding Machine

- Model: HY-EPVW300

- Application: Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards.

- Production Capacity: 20–30 valves per minute.

2. Mechanical Specifications

- Equipment Dimensions:

- Length: 2000 mm

- Width: 1500 mm

- Height: 1800 mm

- Weight: 1200 kg ± 5%

- Frame Material: Industrial-grade steel with powder-coated finish for durability.

- Worktable Material: High-precision aluminum alloy with an anti-static coating.

- Motion System: Servo-controlled X-Y-Z axes for high-accuracy operation.

3. Welding Specifications

- Welding Technology: Precision Fiber Laser Welding.

- Laser Specifications:

- Wavelength: 1064 nm

- Power: 1500W (Spot welding) 1500W, 3000W (Full welding)

- Beam Diameter: 0.1–0.3 mm

- Welding Speed: Up to 3 seconds per weld.

- Welding Accuracy: ±0.02 mm.

- Material Compatibility: Aluminum, stainless steel, and nickel-plated steel.

- Valve Size Compatibility:

- Diameter: 5–50 mm

- Thickness: 0.2–2 mm

4. Loading and Unloading System

- Automation:

- Automatic loading via vibration feeder or robotic arm.

- Pneumatic unloading system for finished parts.

- Capacity:

- Input Hopper: 500 valves per batch.

- Output Bin: 500 welded valves.

5. Vision and Alignment System

- Alignment Accuracy: ±0.02 mm.

- Camera Specifications:

- High-resolution CCD cameras (5 MP) for alignment and inspection.

- Lighting System: Adjustable LED with anti-glare diffusers for optimal visibility.

- Inspection Features:

- Pre-weld alignment verification.

- Post-weld inspection for surface integrity and dimensional accuracy.

6. Control and Interface

- Control System: Advanced PLC-based control with real-time process monitoring.

- HMI:

- 12-inch capacitive touchscreen.

- Multi-language support (English, Chinese, others).

- Programmable Parameters:

- Laser power, focus, and pulse frequency.

- Welding path and cycle time.

- Data Logging:

- Internal Storage: 1 TB SSD for process data.

- Export Formats: CSV, PDF via USB or Ethernet.

7. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 8 kW.

- Control Voltage: 24V DC for auxiliary systems.

8. Safety Features

- Emergency Stop: Multiple emergency stop buttons accessible from all sides.

- Laser Safety:

- Class 1 laser enclosure with interlocks.

- Protective safety glass with an optical density (OD) >5.

- Overload Protection: Real-time monitoring of servo motors and laser systems.

- Protective Barriers: Transparent polycarbonate enclosures.

- Defect Alarms: Audible and visual alerts for misaligned valves or welding defects.

9. Environmental and Installation Requirements

- Operating Environment:

- Temperature: 15–30°C

- Humidity: ≤60% RH (non-condensing).

- Noise Level: ≤70 dB during operation.

- Installation Requirements:

- Flat, vibration-free surface.

- Minimum clearance: 1,000 mm on all sides.

10. Cooling System

- Type: Integrated water cooling system for the laser module.

- Cooling Capacity: 3 kW.

- Water Flow Rate: 10–15 L/min.

- Optional: Air-cooled configuration for smaller-scale operations.

11. Optional Configurations

- Dual Laser Heads: For simultaneous welding of multiple valves.

- Advanced Vision System: AI-powered defect detection and alignment adjustment.

- IoT Connectivity: Remote monitoring and diagnostics via cloud.

- Custom Tooling: For non-standard valve shapes or sizes.

12. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Clean lenses and inspect laser optics.

- Monthly: Calibrate laser parameters and check alignment systems.

- Quarterly: Perform full diagnostics of electrical and mechanical components.

- Warranty Period:

- Standard: 12 months.

- Extended: Up to 36 months available upon request.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

undefined