Solution

Battery Hot Press Equipment

- Product description

-

- Commodity name: Battery Hot Press Equipment

- Commodity ID: 电池热压设备

Precise hot pressing and lamination of prismatic lithium-ion battery cells during assembly processes.

1. Equipment Overview

- Equipment Name: Prismatic Battery Hot Press Equipment

- Model: HY-HP2024

- Application: Precise hot pressing and lamination of prismatic lithium-ion battery cells during assembly processes.

2. Mechanical Specifications

- Equipment Dimensions:

- Length:2000 mm

- Width: 1000 mm

- Height: 2500 mm

- Weight: 2500 kg ± 5%

- Frame Material: High-strength carbon steel with powder-coated finish.

- Actuation System: Precision servo motor with ball screw-driven pressing mechanism.

3. Pressing System

- Pressing Force Range:

- Minimum: 5 kN

- Maximum: 100 kN (adjustable via PLC interface)

- Force Accuracy: ±0.1% (real-time feedback via load cell)

- Pressing Area Dimensions:

- Upper Plate: 300 mm × 400 mm

- Lower Plate: 300 mm × 400 mm

- Parallelism Tolerance: ≤ 0.05 mm

4. Thermal Control System

- Heating Plate Material: Hardened aluminum alloy with embedded thermal sensors.

- Temperature Control Range: Room temperature to 250°C.

- Temperature Control Method: PID controller with real-time feedback.

- Heating Rate: ≤ 5°C/s (adjustable).

- Temperature Uniformity:

- Across Plate Surface: ±2°C

- Stability: ±0.5°C

7. Process Control System

- Control Interface:

- 10-inch TFT touch screen display.

- Multi-language support: English, Chinese, etc.

- Programmable Parameters:

- Temperature profiles (up to 5 stages).

- Pressing force/time sequences.

- Cooling cycles.

- Data Logging:

- Internal storage capacity: 2 GB (up to 100,000 cycles).

- Export Format: CSV via USB or Ethernet.

8. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 50 kW

- Control Voltage: 24V DC for safety and signal integrity.

9. Safety Features

- Emergency Stop: Dual redundant emergency stop buttons.

- Overload Protection:

- Real-time pressure monitoring.

- Automatic shutdown on force deviation >10%.

- Temperature Safety: Independent thermal fuse and overheat alarm at 260°C.

- Operator Safety: Protective safety shields with interlock switches.

10. Environment & Installation

- Operating Environment:

- Temperature: 10–35°C

- Humidity: ≤70% RH (non-condensing).

- Noise Level: ≤70 dB under standard operation.

- Installation Requirements:

- Level concrete foundation.

- Minimum clearance: 500 mm on all sides.

11. Optional Configurations

- Mold Customization: Precision molds tailored to customer specifications.

- IoT Connectivity: Real-time monitoring and diagnostics via cloud platform.

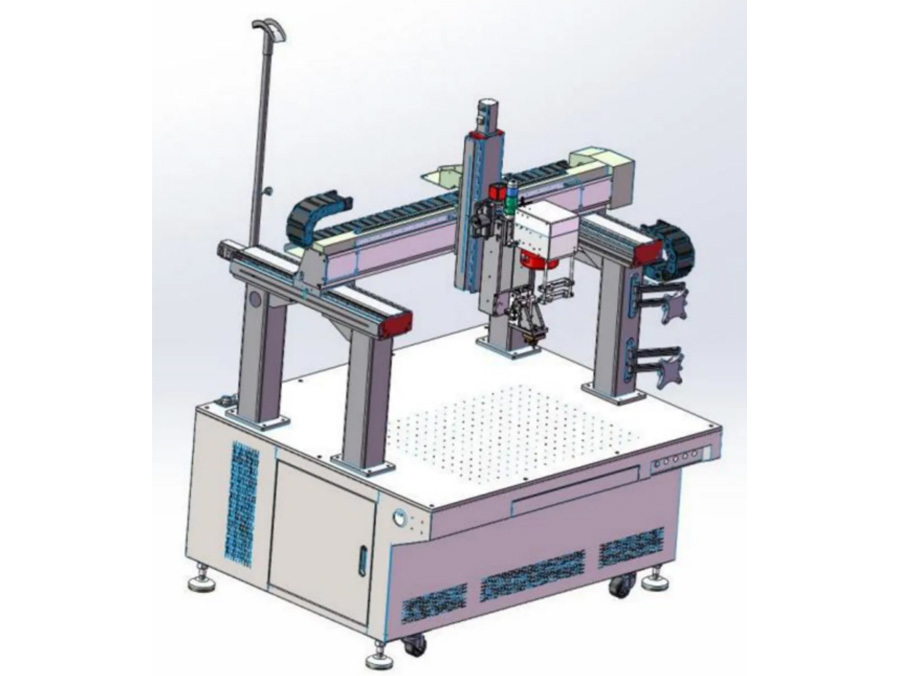

- Automatic Loading/Unloading: Robotic module integration for higher throughput.

12. Maintenance and Warranty

- Scheduled Maintenance:

- Heating elements: Every 12 months.

- Pressing mechanism lubrication: Every 6 months.

- Warranty Period:

- Standard: 12 months.

- Extended options available.

Key words:

Battery Hot Press Equipment

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

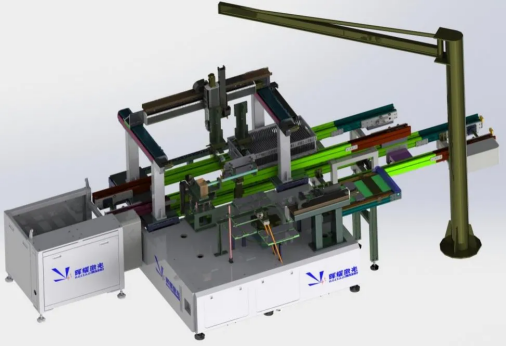

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6