Solution

MES Solution for ESS Smart Factory

- Product description

-

- Commodity name: MES Solution for ESS Smart Factory

- Commodity ID: 储能电池智能工厂MES系统

The MES (Manufacturing Execution System) for ESS Smart Factory Solution is a comprehensive software platform designed to optimize production processes in energy storage system (ESS) manufacturing facilities.

1. Overview

The MES (Manufacturing Execution System) for ESS Smart Factory Solution is a comprehensive software platform designed to optimize production processes in energy storage system (ESS) manufacturing facilities. This system integrates seamlessly with factory hardware and software, providing real-time monitoring, traceability, data analytics, and process control to ensure efficiency, quality, and scalability.

2. Key Features

- Real-Time Monitoring: Tracks production, equipment status, and material flow in real time.

- End-to-End Traceability: Provides detailed records of production from raw materials to finished products.

- Data Analytics and Reporting: Offers actionable insights for process optimization and decision-making.

- Seamless Integration: Interfaces with ERP, PLM, SCADA, and other systems.

- Scalability: Adapts to varying production scales and product lines.

3. Technical Specifications

3.1 System Architecture

- Platform: Cloud-based or on-premises deployment options.

- Core Modules:

- Production Management.

- Quality Management.

- Equipment Management.

- Inventory and Logistics Control.

- Data Analysis and Reporting.

- Traceability and Genealogy.

- Database: Supports MySQL, PostgreSQL, SQL Server, or Oracle.

3.2 Hardware Requirements

- Server Requirements:

- CPU: Minimum 8-core, 3.0 GHz.

- RAM: 32 GB or more.

- Storage: SSD with 2 TB capacity.

- Network: 1 Gbps Ethernet.

- Client Devices:

- Supported on PCs, tablets, and mobile devices.

- Browser Compatibility: Chrome, Edge, Firefox (latest versions).

3.3 Functional Specifications

3.3.1 Production Management

- Work Order Tracking: Real-time tracking of work orders and production stages.

- Process Control: Monitors compliance with predefined manufacturing processes.

- Resource Allocation: Ensures optimal utilization of machines and labor.

3.3.2 Quality Management

- Defect Detection: Logs defects and automates alerts for corrective actions.

- SPC (Statistical Process Control): Monitors key quality parameters to ensure consistency.

- Inspection Management: Configurable workflows for inline and end-of-line inspections.

3.3.3 Equipment Management

- Predictive Maintenance: Utilizes machine data to predict and schedule maintenance.

- Downtime Analysis: Tracks and categorizes downtime to improve OEE (Overall Equipment Effectiveness).

- Integration: Interfaces with IoT devices for real-time equipment data collection.

3.3.4 Traceability

- Batch and Serial Tracking: Monitors material flow across production lines.

- Genealogy: Links components and processes to finished products for complete traceability.

- Regulatory Compliance: Generates audit trails for certifications and reporting.

3.3.5 Inventory and Logistics Control

- Material Flow Optimization: Real-time updates on inventory levels and usage.

- Warehouse Management: Supports raw material, WIP (Work-in-Progress), and finished goods tracking.

- Supply Chain Integration: Interfaces with ERP systems for seamless material management.

3.4 Communication Protocols

- Supported Protocols: OPC UA, Modbus, MQTT, RESTful API, and WebSocket.

- BMS Integration: Supports CAN, RS485, and Ethernet communication.

- ERP/SCADA Integration: Prebuilt adapters for SAP, Oracle, and Siemens systems.

3.5 Security

- Authentication: Multi-factor authentication (MFA) for secure access.

- Encryption: AES-256 encryption for data transmission and storage.

- Backup and Recovery: Automated backup schedules and disaster recovery protocols.

3.6 Scalability and Performance

- Concurrent Users: Supports up to 500 simultaneous users.

- System Load: Capable of managing 1 million production data points per day.

- Customization: Flexible modules for future expansion and additional functionalities.

3.7 Data Analytics and Reporting

- Real-Time Dashboards: Interactive dashboards for KPIs, including yield rates, cycle times, and OEE.

- Custom Reports: Configurable templates for production, quality, and inventory reporting.

- AI Integration: Optional machine learning algorithms for predictive insights.

4. Applications

- ESS Battery Production: Enhances production efficiency for energy storage systems.

- Quality Assurance: Ensures compliance with industry standards.

- Traceability: Simplifies audits and certifications for regulatory compliance.

- Operational Optimization: Identifies bottlenecks and streamlines workflows.

5. Maintenance and Support

- Software Updates: Regular updates for security patches and new features.

- Technical Support: 24/7 support via phone, email, and remote access.

- Training: Comprehensive training for operators and administrators.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

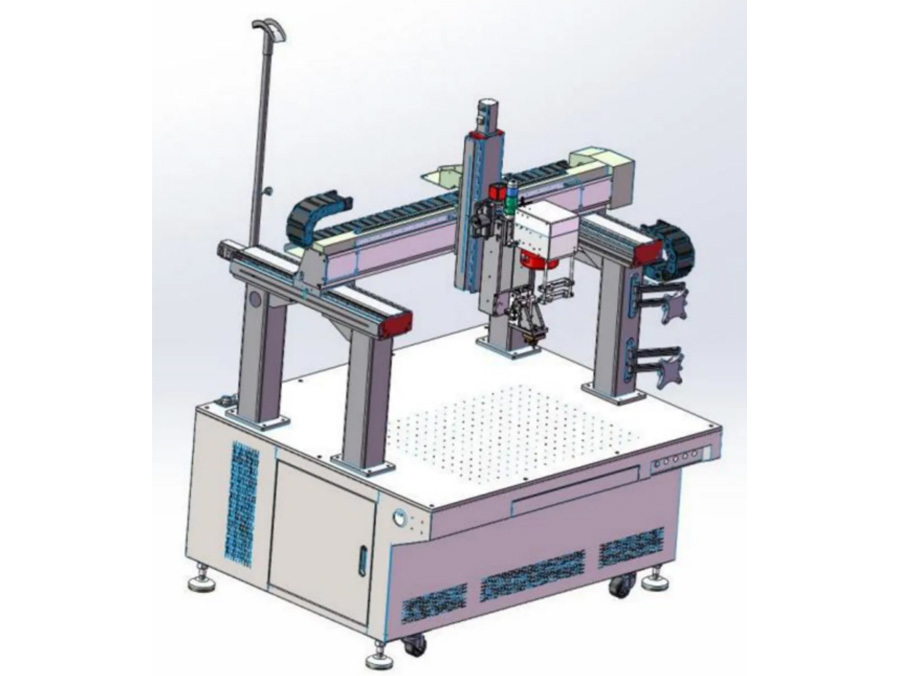

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A