Solution

AS/RS Solution

- Product description

-

- Commodity name: AS/RS Solution

- Commodity ID: 5.1.立体仓库

Automated Storage and Retrieval Systems (AS/RS) are an essential part of modern battery PACK factories.

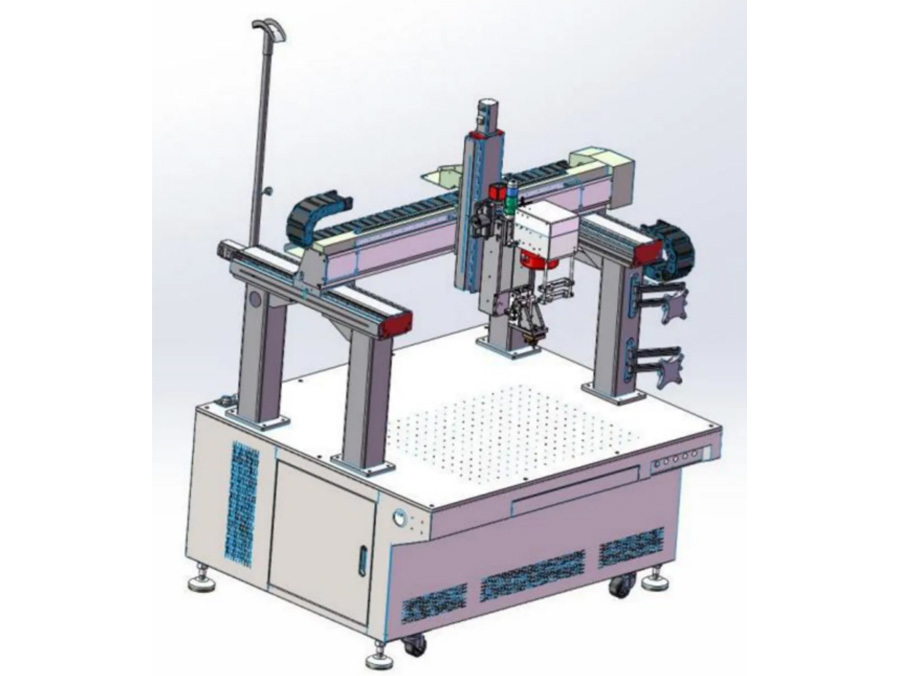

Automated Storage and Retrieval Systems (AS/RS) are an essential part of modern battery PACK factories. They provide efficient, automated solutions for storing and retrieving battery modules, PACKs, and related materials. These systems are designed to enhance productivity, reduce manual labor, and optimize space utilization in storage facilities.

Key Features of AS/RS in Battery PACK Factories

Precision Storage:

AS/RS ensures that battery modules and PACKs are stored systematically, with minimal risk of damage. They use automated controls and robotics to manage the precise placement and retrieval of items.Temperature and Humidity Control:

Many AS/RS setups in battery factories include environmental controls to maintain optimal conditions for sensitive battery components.High-Density Storage:

AS/RS systems maximize vertical and horizontal space usage, providing high-density storage solutions for compact or large-scale operations.Integration with Manufacturing Execution Systems (MES):

The AS/RS seamlessly integrates with MES, enabling real-time tracking and monitoring of inventory levels, movement, and storage conditions.Safety Compliance:

Equipped with safety protocols and fire protection systems, AS/RS in battery factories adheres to stringent safety standards for handling and storing potentially hazardous materials.Benefits of Using AS/RS for Battery PACK Storage

Efficiency and Speed:

Automated retrieval systems ensure rapid and accurate access to stored items, reducing downtime and delays in the production process.Improved Inventory Management:

Integrated software provides real-time inventory tracking, ensuring accurate stock levels and minimizing material shortages or overstocking.Space Optimization:

By utilizing vertical storage and eliminating the need for wide aisles, AS/RS systems significantly improve space utilization.Reduced Labor Costs:

Automation minimizes the need for manual labor, lowering operational costs while enhancing efficiency.Minimized Risk of Damage:

The precision of AS/RS reduces the handling of battery modules and PACKs, minimizing the risk of physical damage or accidents.Enhanced Safety:

Automated systems handle heavy or hazardous materials with minimal human intervention, reducing workplace safety risks.Applications in Battery PACK Factories

Raw Material Storage:

AS/RS is used to store incoming raw materials like battery cells, casings, and other components, ensuring an organized flow into the production line.Work-in-Progress (WIP) Storage:

Temporary storage of semi-finished battery modules or PACKs between production stages.Finished Goods Storage:

After assembly and testing, completed battery PACKs are stored for shipping or further processing.Recycling and Defective Material Handling:

AS/RS can also store defective components or items designated for recycling, ensuring segregation from production-ready inventory.Why Implement AS/RS in Battery PACK Factories?

As the demand for EVs and energy storage systems grows, battery PACK factories need scalable and efficient solutions for handling high volumes of materials. AS/RS provides the automation and control necessary to meet these demands while maintaining quality and safety standards.

By investing in AS/RS, factories can ensure streamlined operations, improve material traceability, and align with Industry 4.0 principles, enabling smart and sustainable manufacturing practices.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A