Solution

EV Cylindrical Battery Module PACK Assembly Line

- Product description

-

- Commodity name: EV Cylindrical Battery Module PACK Assembly Line

- Commodity ID: 3.2动力大圆柱电池模组PACK线

The EV Cylindrical Battery Module PACK Assembly Line is a fully automated production system designed for efficient assembly of cylindrical cells into battery modules and packs.

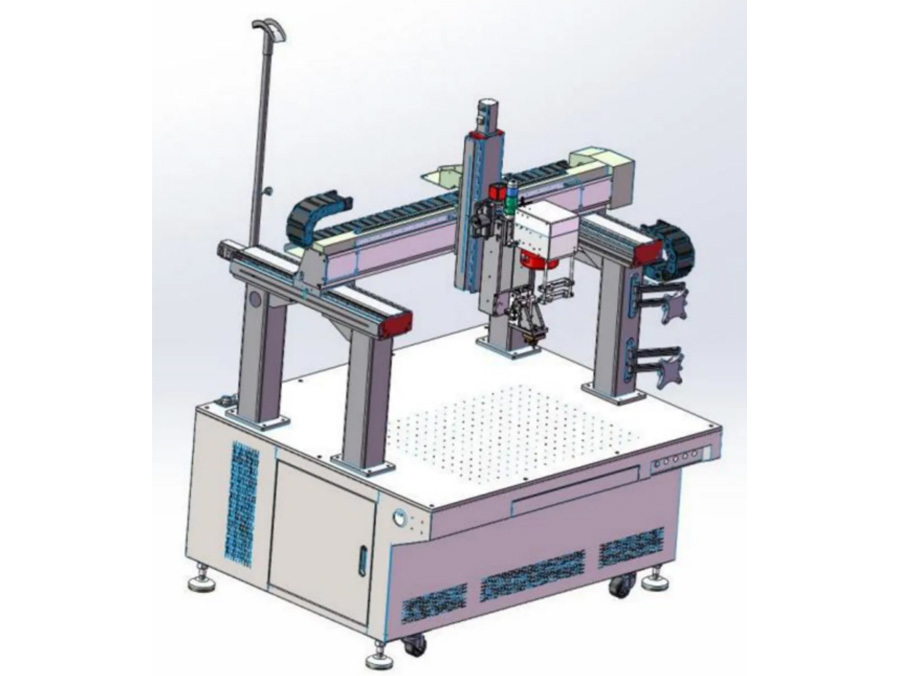

1. Equipment Overview

The EV Cylindrical Battery Module PACK Assembly Line is a fully automated production system designed for efficient assembly of cylindrical cells into battery modules and packs. It incorporates cell sorting, grouping, module assembly, electrical interconnection, testing, and PACK assembly to ensure high precision, traceability, and reliability. This line is optimized for EV applications with flexible configurations and integrated quality assurance systems.

2. Key Features

- High Throughput: Fully automated line ensures consistent production efficiency.

- Flexibility: Supports various cylindrical cell sizes (e.g., 18650, 21700, 4680).

- Precision Welding: Advanced laser welding for interconnect reliability.

- Quality Assurance: Inline testing and inspection at multiple stages.

- Smart Integration: MES system compatibility for real-time data and process control.

3. Technical Specifications

3.1 Cell Sorting and Grouping

- Sorting Accuracy:

- Voltage: ±0.01 V.

- Capacity: ±0.1 Ah.

- Internal Resistance: ±0.1 mΩ.

- Sorting Capacity: Up to 1,200 cells/hour.

- Grouping Strategy: Automatic grouping by voltage, capacity, and resistance for balanced modules.

3.2 Module Assembly

- Cell Arrangement: Supports various configurations, including parallel and series arrangements.

- Fixture Accuracy: ±0.2 mm alignment for cylindrical cells.

- Adhesive Application: Automated dispensing of thermal adhesive for structural integrity and heat dissipation.

- Cycle Time: ≤40 seconds/module.

3.3 Electrical Interconnection

- Connection Method:

- Laser welding for busbar connections.

- Optional ultrasonic welding for tab-to-tab connections.

- Welding Precision: ±0.1 mm.

- Busbar Material: Nickel or copper with optional conductive coatings.

- Conductivity: ≤0.2 mΩ per connection.

3.4 PACK Assembly

- PACK Design:

- Customizable configurations for EV applications (e.g., 8s1p, 16s2p, etc.).

- Casing Assembly: Automatic alignment and fastening of PACK enclosures.

- Thermal Management Integration:

- Liquid cooling plates or air-cooling channels added during assembly.

3.5 Integrated Testing and Inspection

- Inline Testing:

- Voltage, current, and internal resistance measurement.

- Welding strength verification.

- High-Pot Testing:

- Voltage Range: 0–1,000 V DC.

- Insulation Resistance: 0.1 MΩ–1 GΩ, ±1%.

- Leakage Testing: Air tightness check with sensitivity of 1 × 10⁻³ Pa·m³/s.

- Visual Inspection: Camera-based inspection for welding and assembly defects.

3.6 Automation and Control

- Control System: PLC-based with integrated HMI for real-time monitoring and operation.

- Data Management: MES integration for production tracking and traceability.

- Alarm System: Automated fault detection with alerts for process deviations.

- Programmable Recipes: Supports multiple product configurations with minimal changeover time.

3.7 Line Capacity and Efficiency

- Production Rate: Up to 200 modules/day or 100 PACKs/day (depending on configuration).

- Uptime Efficiency: ≥98%.

- Changeover Time: ≤20 minutes for different configurations.

3.8 Safety Features

- Emergency Stop: Strategically placed emergency stop buttons.

- Laser Safety: Enclosed laser stations with Class 1 safety compliance.

- High-Voltage Safety: Insulated workstations and automated power cut-off during testing.

- Certifications: CE, UL, ISO 9001, ISO 14001 compliant.

3.9 Mechanical Design

- Line Layout: Modular, customizable layout ranging from 30–80 meters.

- Material Handling: Conveyor system with anti-static trays.

- System Weight: 8,000–20,000 kg depending on configuration.

3.10 Environmental Requirements

- Operating Temperature: 15–35°C.

- Humidity: ≤60% RH (non-condensing).

- Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

- Power Consumption: ≤120 kW.

4. Applications

- Electric Vehicles: Cylindrical battery module and PACK assembly for EV powertrains.

- Energy Storage: Modules for renewable energy storage systems.

- Industrial Applications: Battery PACKs for robotics, backup power, and industrial automation.

5. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspection and cleaning of key components.

- Monthly: Calibration of measurement tools and welding equipment.

- Annually: Comprehensive diagnostics and software updates.

- Warranty:

- Standard: 1 year.

- Extended: Customizable based on service agreement.

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A