Solution

EV Cylindrical Battery Module PACK Assembly Line

- Product description

-

- Commodity name: EV Cylindrical Battery Module PACK Assembly Line

- Commodity ID: 动力大圆柱电池模组PACK线

Sorts cylindrical cells based on voltage, internal resistance, and capacity to ensure balanced modules.

1. Equipment Overview

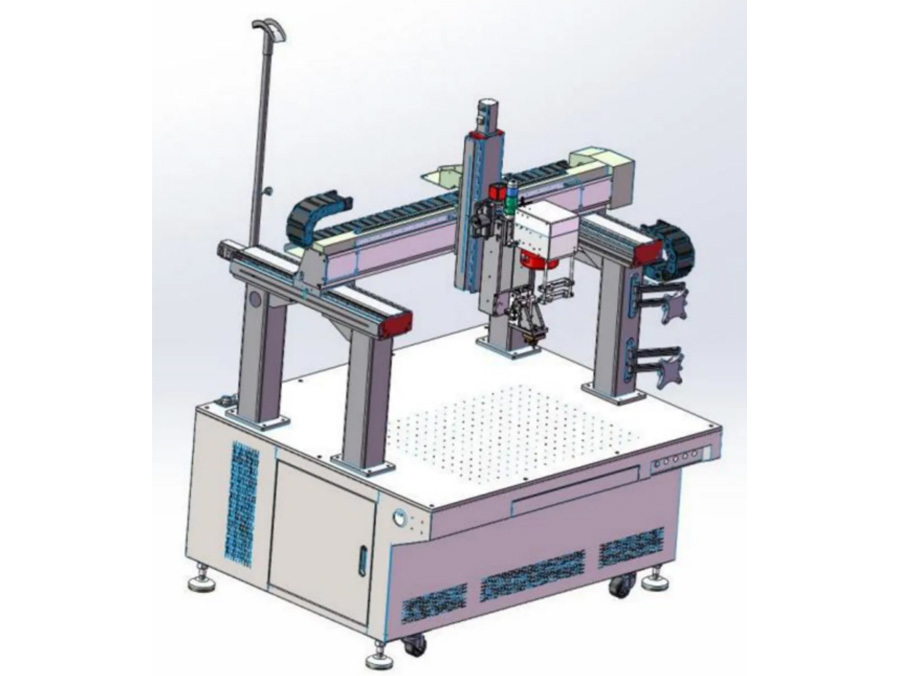

The EV Cylindrical Battery Module PACK Assembly Line is a state-of-the-art automated system designed for assembling cylindrical battery cells into modules and complete PACKs. It encompasses cell sorting, welding, module stacking, PACK integration, and comprehensive testing, ensuring high efficiency, precision, and safety for EV battery manufacturing.

2. Key Processes and Modules

2.1 Battery Cell Sorting Station

- Function: Sorts cylindrical cells based on voltage, internal resistance, and capacity to ensure balanced modules.

- Specifications:

- Sorting Accuracy: ±1 mV (voltage), ±0.1 mΩ (resistance).

- Sorting Throughput: 1200 cells/hour.

2.2 Cell Grouping and Holder Insertion

- Function: Groups cells based on sorting data and inserts them into plastic or metal holders.

- Specifications:

- Cell Diameter Range: 18–46 mm.

- Holder Positioning Accuracy: ±0.1 mm.

- Cycle Time: ≤5 seconds per cell.

2.3 Busbar Placement and Welding

- Function: Places busbars on cell terminals and welds them for electrical connections.

- Specifications:

- Welding Method: Laser welding or resistance welding.

- Welding Power: 600 W (resistance welding).

- Welding Accuracy: ±0.05 mm.

- Welding Speed: ≤5 seconds per weld.

2.4 Cooling Plate and Thermal Interface Material (TIM) Application

- Function: Installs cooling plates and applies TIM for thermal management.

- Specifications:

- TIM Application Accuracy: ±0.1 mm.

- Cooling Plate Compatibility: Aluminum, copper.

- Cycle Time: ≤20 seconds per module.

2.5 PACK Assembly and Integration

- Function: Integrates modules into the battery PACK, including high-voltage connectors and housing.

- Specifications:

- PACK Size Range:

- Length: 600–1200 mm.

- Width: 400–800 mm.

- Height: 150–500 mm.

- Positioning Accuracy: ±0.3 mm.

- Cycle Time: ≤120 seconds per PACK.

- PACK Size Range:

2.6 Final Testing and Inspection

- Function: Conducts comprehensive electrical and safety tests on the final PACK.

- Specifications:

- Test Parameters: Voltage, current, insulation resistance, short-circuit protection, and helium leak detection.

- Testing Speed: ≤2 minutes per PACK.

- Pass/Fail Criteria: Programmable through the central control system.

3. Production Line Specifications

- Overall Dimensions:

- Length: 35000 mm.

- Width: 5000 mm.

- Height: 3,500 mm.

- Weight: Approximately 30,000 kg.

- Production Capacity: Up to 25 PACKs/hour.

- Automation Level: Fully automated with robotic systems.

4. Vision and Quality Inspection Systems

- Alignment Cameras:

- Accuracy: ±0.02 mm for cell placement and module stacking.

- Resolution: 12 MP.

- Defect Detection: Algorithms for welding, misalignment, and surface defects.

- Data Logging: Inspection results stored for traceability.

5. Control and Interface

- Control System: Centralized PLC with decentralized modules for each station.

- Human-Machine Interface (HMI):

- 15-inch touchscreen with multi-language support.

- Real-time monitoring and troubleshooting.

- IoT Connectivity:

- Remote diagnostics, production tracking, and analytics via cloud integration.

6. Safety Features

- Enclosures: Fully enclosed stations with interlocks.

- Emergency Stops: Strategically placed across the line.

- Laser Safety: Class 1 laser protection with certified viewing windows.

- Overcurrent Protection: Built-in sensors to prevent electrical overloads.

7. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 180 kW.

- Control Voltage: 24V DC for auxiliary systems.

8. Cooling System

- Type: Centralized water cooling for welding systems and power electronics.

- Cooling Capacity: 18 kW.

- Flow Rate: 65 L/min.

9. Environmental Requirements

- Operating Environment:

- Temperature: 15–30°C.

- Humidity: ≤60% RH (non-condensing).

- Noise Level: ≤75 dB during operation.

- Installation Space: Minimum clearance of 2,000 mm around the line.

10. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspect welding systems, alignment mechanisms, and cooling systems.

- Monthly: Calibrate vision and testing equipment.

- Quarterly: Comprehensive diagnostics of the entire line.

- Warranty Period:

- Standard: 12 months.

- Extended: Up to 36 months available upon request.

Key words:

EV Cylindrical Battery Module PACK Assembly Line

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

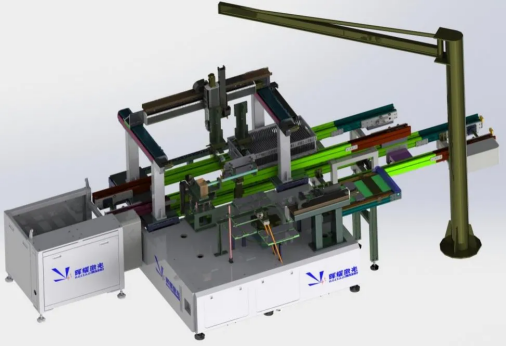

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6