Solution

EV Battery Module PACK End-of-Line (EOL) Testing System

- Product description

-

- Commodity name: EV Battery Module PACK End-of-Line (EOL) Testing System

- Commodity ID: 动力电池模组PACK电芯EOL测试系统

The Battery Module PACK End-of-Line (EOL) Testing System is a fully integrated solution designed to validate the quality, safety, and performance of battery modules and PACKs at the final stage of production.

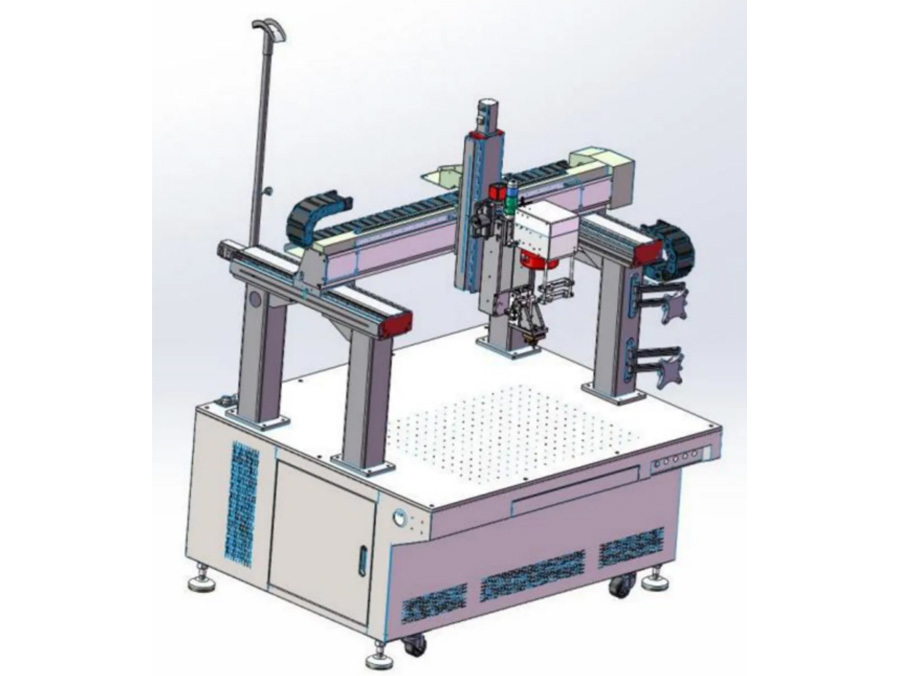

1. Equipment Overview

The Battery Module PACK End-of-Line (EOL) Testing System is a fully integrated solution designed to validate the quality, safety, and performance of battery modules and PACKs at the final stage of production. It performs comprehensive tests to ensure the product meets specified standards before shipping, covering electrical, thermal, and mechanical parameters, as well as communication functionality.

2. Key Features

- Comprehensive Testing: Combines electrical performance, communication, insulation, and safety tests.

- High Precision: Accurate measurement of voltage, current, and resistance.

- Multi-Protocol Support: Compatible with common communication standards (CAN, RS485, etc.).

- Automated Operations: Streamlined processes for fast and efficient testing.

- Customizable Profiles: Configurable test sequences based on customer requirements.

3. Technical Specifications

3.1 Electrical Performance Testing

- Voltage Measurement Range: 0–1,000 V DC.

- Accuracy: ±0.05%.

- Current Measurement Range: 0–300 A DC (configurable for higher currents).

- Accuracy: ±0.1%.

- Capacity Range: 10 Ah–500 Ah.

- Internal Resistance Measurement:

- Range: 0.1 mΩ–1 Ω.

- Accuracy: ±0.5%.

- Power Capability: Up to 200 kW.

3.2 Communication Testing

- Supported Protocols: CAN, RS485, LIN, Ethernet.

- Baud Rate: Up to 1 Mbps (CAN).

- Data Logging: Monitors communication signals for errors and integrity.

- Protocol Customization: Supports proprietary communication protocols.

3.3 Safety and Insulation Testing

- Insulation Resistance Test:

- Voltage: Up to 1,000 V DC.

- Range: 0.1 MΩ–1 GΩ.

- Accuracy: ±1%.

- Dielectric Withstand Voltage Test (HiPot):

- Voltage: Up to 5,000 V AC/DC.

- Leakage Current: ≤1 mA.

- Short-Circuit Protection Test: Verifies PACK safety mechanisms.

3.4 Functional Testing

- Charge-Discharge Testing: Simulates real-world operating conditions.

- Programmable Cycles: Up to 10,000.

- Dynamic Load Simulation: Replicates operational profiles.

- Thermal Behavior: Measures thermal stability under various conditions.

- Temperature Range: -10°C to 80°C (optional integrated thermal chamber).

- Accuracy: ±1°C.

3.5 Software and Control

- User Interface:

- 15-inch touchscreen HMI with an intuitive design.

- Multi-language support (English, Chinese, etc.).

- Data Management:

- Real-time monitoring with graphical analysis.

- Historical data storage for traceability.

- Export formats: CSV, Excel, PDF.

- Test Programming: Configurable test parameters and sequences.

- Remote Access: Ethernet, USB, and Wi-Fi for data transfer and monitoring.

3.6 Mechanical Design

- System Configuration:

- Modular structure for scalability.

- Adjustable fixtures for various module and PACK dimensions.

- Capacity: Up to 16 modules/PACKs per cycle.

- Dimensions:

- Length: 2,000–4,000 mm.

- Width: 1,200–2,000 mm.

- Height: 2,000 mm.

- Weight: 1,500–3,000 kg.

3.7 Safety Features

- Overvoltage/Overcurrent Protection: Prevents damage to modules or equipment.

- Emergency Stop: Accessible emergency shutdown for operators.

- Environmental Monitoring: Includes smoke detectors and temperature sensors.

- Certifications: CE, UL, ISO 9001 compliant.

3.8 Environmental Requirements

- Operating Temperature: 10–35°C.

- Humidity: ≤60% RH (non-condensing).

- Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

- Power Consumption: ≤50 kW.

4. Applications

- EV Battery Production: Ensures compliance with quality and safety standards.

- Energy Storage Systems (ESS): Validates the performance of grid-scale battery systems.

- Consumer Electronics: Assesses battery modules for small-scale applications.

- R&D and Quality Assurance: Supports product development and quality consistency.

5. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspect connectors, sensors, and fixtures.

- Monthly: Calibrate voltage, current, and resistance measurement systems.

- Annually: Perform comprehensive diagnostics and software updates.

- Warranty Period:

- Standard: 12 months.

- Extended: Available upon request.

Key words:

EV Battery Module PACK End-of-Line (EOL) Testing System

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

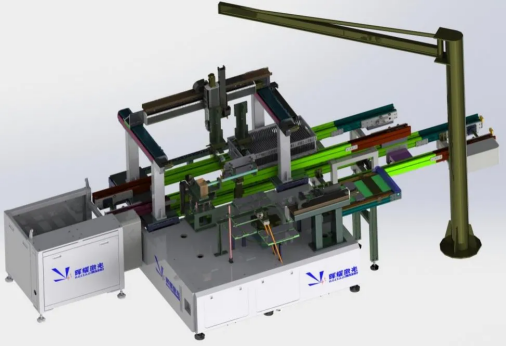

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6