Product

EV Battery Cell Performance Testing Cabinet

- Product description

-

- Commodity name: EV Battery Cell Performance Testing Cabinet

- Commodity ID: 动力电芯性能测试柜

The Battery Cell Performance Testing Cabinet is designed for comprehensive performance evaluation of battery cells, ensuring high reliability and precision.

1. Equipment Overview

The Battery Cell Performance Testing Cabinet is designed for comprehensive performance evaluation of battery cells, ensuring high reliability and precision. It supports tests for electrical, thermal, and durability performance under configurable charge-discharge cycles. This equipment is widely used in EV battery manufacturing, energy storage systems (ESS), and consumer electronics.

2. Key Features

- Comprehensive Testing: Voltage, current, capacity, resistance, and cycle life analysis.

- High Precision: Accurate performance measurement under various conditions.

- Dynamic Testing: Simulates real-world usage scenarios.

- Automation: Fully automated test cycles and data logging.

- Safety Integration: Multi-level safety protocols for operator and equipment protection.

3. Technical Specifications

3.1 Electrical Performance Testing

- Voltage Range: 0–5 V (configurable).

- Voltage Accuracy: ±0.05%.

- Current Range: 0.1–100 A (configurable).

- Current Accuracy: ±0.1%.

- Capacity Measurement:

- Range: 100 mAh – 300 Ah.

- Accuracy: ±0.2%.

- Internal Resistance Measurement:

- Range: 0.1 mΩ–1 Ω.

- Accuracy: ±0.5%.

3.2 Cycle Life Testing

- Cycle Modes: Constant current, constant voltage, and custom profiles.

- Cycle Count Range: 1–10,000 cycles.

- Data Recording: Voltage, current, and capacity logged in real time.

- Cycle Time Accuracy: ±0.1%.

3.3 Thermal Testing

- Temperature Range: -20°C to 60°C (optional integrated chamber).

- Accuracy: ±0.5°C.

- Thermal Management: Real-time temperature control for testing thermal performance and runaway scenarios.

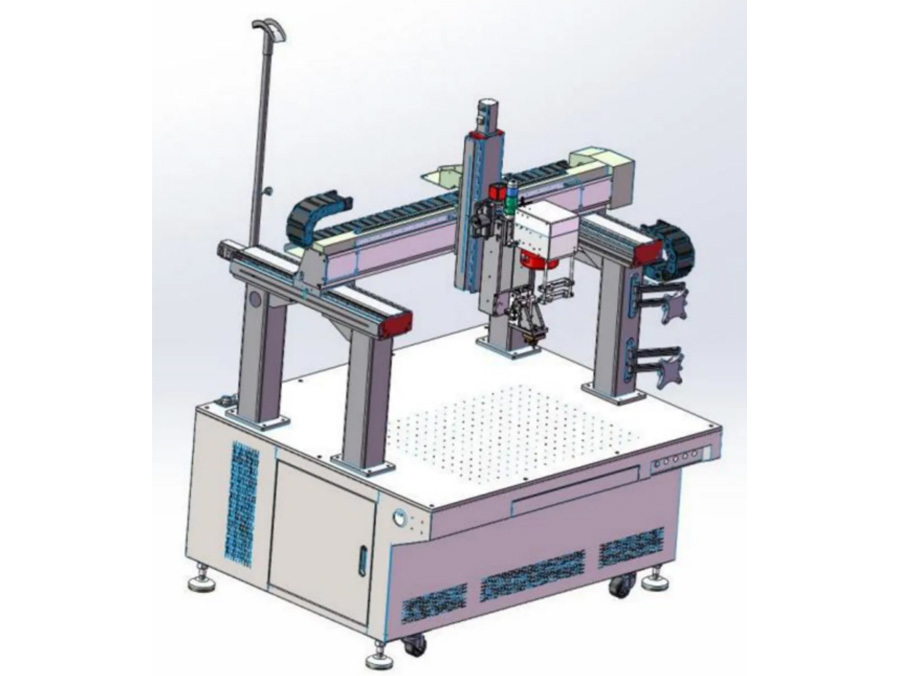

3.4 Mechanical Design

- Cabinet Configuration:

- Multi-channel layout for simultaneous cell testing.

- Adjustable fixtures to accommodate different cell sizes.

- Capacity: 32–256 channels (expandable).

- Dimensions:

- Length: 1,500–2,000 mm.

- Width: 800–1,000 mm.

- Height: 2,000 mm.

- Weight: 800–1,500 kg (depends on configuration).

3.5 Software and Control

- Interface:

- 15-inch touchscreen HMI.

- Multi-language support (English, Chinese, etc.).

- Programming: Flexible setup for custom test sequences and parameters.

- Data Management:

- Real-time monitoring with graphical representation.

- Export formats: CSV, Excel, PDF.

- Cloud storage and IoT-ready for remote access.

- Connectivity: Ethernet, USB, and Wi-Fi options.

3.6 Safety Features

- Overvoltage and Overcurrent Protection: Prevents damage to cells and equipment.

- Short-Circuit Detection: Immediate shutdown in case of faults.

- Thermal Shutdown: Automatic safety measures for overheating.

- Emergency Stop: Operator-accessible safety shutdown.

- Certifications: CE, UL, ISO 9001 compliant.

3.7 Electrical Specifications

- Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 15–50 kW (depends on configuration).

- Control Voltage: 24V DC for sensors and peripherals.

3.8 Environmental Requirements

- Operating Temperature: 10–35°C.

- Humidity: ≤60% RH (non-condensing).

- Ventilation: Integrated system for heat and airflow management.

4. Applications

- EV Battery Testing: Performance validation for prismatic, cylindrical, and pouch cells.

- Energy Storage Systems: Evaluation of cells used in grid-scale storage.

- Consumer Electronics: Testing small battery cells for portable devices.

5. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspect connectors, fixtures, and monitoring systems.

- Monthly: Verify calibration of voltage, current, and resistance measurements.

- Annually: Comprehensive diagnostic checks and software updates.

- Warranty Period:

- Standard: 12 months.

- Extended: Available on request.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

Can these lines handle different prismatic cell sizes or chemistries (LFP, M3P)?

A

Q

How do I choose the "best" prismatic assembly line?

A