Solution

ESS Battery Module PACK BMS Testing System

- Product description

-

- Commodity name: ESS Battery Module PACK BMS Testing System

- Commodity ID: 储能电池模组PACK BMS系统测试系统

The ESS Battery Module PACK BMS Testing System is designed to evaluate the functionality, performance, and reliability of Battery Management Systems (BMS) used in energy storage system (ESS) modules and packs.

1. Equipment Overview

The ESS Battery Module PACK BMS Testing System is designed to evaluate the functionality, performance, and reliability of Battery Management Systems (BMS) used in energy storage system (ESS) modules and packs. It ensures proper communication, safety, and efficiency of the BMS, which is crucial for maintaining battery health and preventing malfunctions in ESS applications.

2. Key Features

- Comprehensive BMS Testing: Verifies communication, protection mechanisms, balancing performance, and more.

- Protocol Compatibility: Supports common BMS communication protocols such as CAN, RS485, RS232, and Ethernet.

- Customizable Testing Profiles: Tailored to ESS application needs and BMS specifications.

- High Accuracy and Speed: Precise simulation of real-world operating conditions.

- Integrated Data Management: Facilitates seamless data collection, analysis, and reporting.

3. Technical Specifications

3.1 BMS Communication Testing

- Supported Protocols:

- CAN 2.0A/2.0B, CAN FD.

- RS485, RS232.

- Ethernet TCP/IP.

- Communication Speed:

- CAN: Up to 1 Mbps.

- Ethernet: Up to 1 Gbps.

- Addressable Nodes: Up to 256 nodes.

3.2 Electrical Testing Parameters

- Voltage Simulation:

- Range: 0–1,000 V.

- Accuracy: ±0.05%.

- Current Simulation:

- Range: 0–300 A.

- Accuracy: ±0.1%.

- Cell Balancing Testing:

- Range: 0–500 mA.

- Accuracy: ±0.05%.

- Thermal Simulation:

- Temperature Range: -20°C to 80°C (optional).

3.3 Functional Testing

- Key Functions Verified:

- Overvoltage/undervoltage protection.

- Overcurrent/short-circuit protection.

- Temperature monitoring and control.

- SOC (State of Charge) and SOH (State of Health) algorithms.

- Fault diagnosis and alert mechanisms.

- Cycle Testing:

- Simulates real-world charge and discharge cycles to validate performance.

3.4 System Capacity

- Parallel Channels:

- Standard: 16–64 channels (expandable).

- Independent operation for each channel.

- Maximum Packs Tested Simultaneously: Up to 50 (depending on configuration).

3.5 Data Management

- Data Logging: Real-time recording of voltage, current, temperature, and communication logs.

- Traceability: Unique ID tracking for each BMS module.

- Reporting: Automated generation of detailed test reports.

- Integration: MES/ERP-compatible for centralized data management.

3.6 Control System

- HMI: 10.1-inch touchscreen for intuitive operation.

- Control Platform: PLC/PC-based for reliable control and automation.

- Customizable Test Profiles: Preloaded and user-defined profiles for various ESS applications.

3.7 Safety Features

- Electrical Protections: Overcurrent, overvoltage, and short-circuit protections.

- Thermal Monitoring: Integrated sensors to detect and alert temperature anomalies.

- Emergency Shutdown: Accessible buttons to terminate testing immediately.

- Isolation Design: Ensures safety between channels during testing.

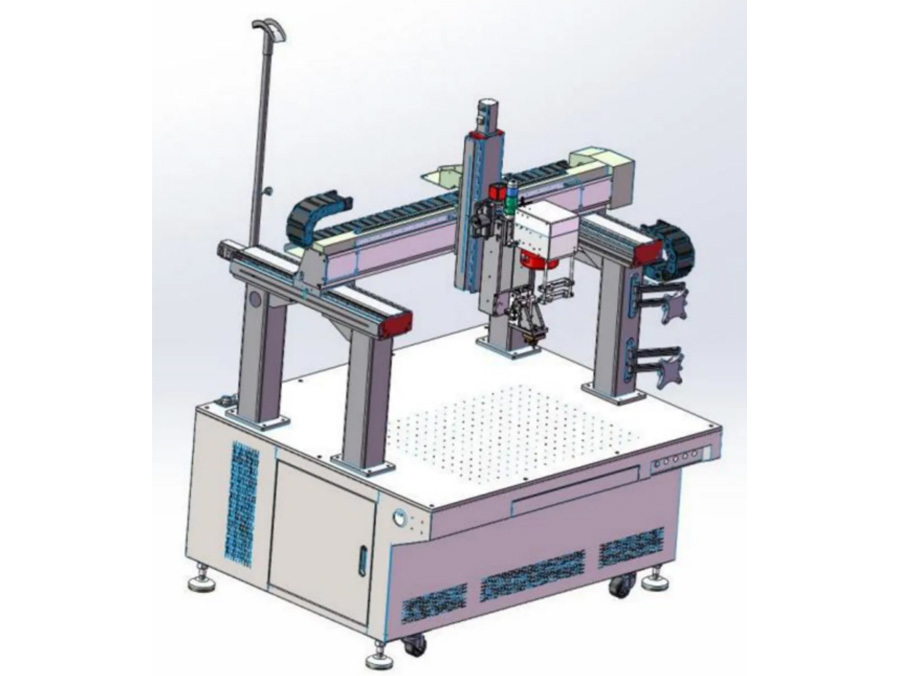

3.8 Mechanical Design

- Dimensions: 2,000 × 1,200 × 2,000 mm (customizable).

- Weight: Approximately 2,000 kg.

- Cabinet Structure: Modular design for ease of operation and maintenance.

- Cooling System: Forced-air or liquid cooling for stable operation.

3.9 Power Requirements

- Input Voltage: AC 380V ±10%, 50/60 Hz, 3-phase.

- Power Consumption: ≤50 kW.

3.10 Environmental Requirements

- Operating Temperature: 15–35°C.

- Humidity: ≤70% RH (non-condensing).

- Clean Environment: Dust-free and vibration-free area recommended

4. Applications

- Energy Storage Systems (ESS): Ensures optimal performance of BMS for grid-scale storage.

- Renewable Energy Storage: Validates BMS for solar and wind power integration.

- Industrial and Commercial ESS: Supports testing for BMS in large-scale projects.

5. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Check connectors and communication ports.

- Monthly: Calibration of electrical and thermal simulation parameters.

- Annually: Comprehensive system diagnostics and software updates.

- Warranty:

- Standard: 1 year.

- Extended: Available upon request.

Key words:

ESS Battery Module PACK BMS Testing System

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

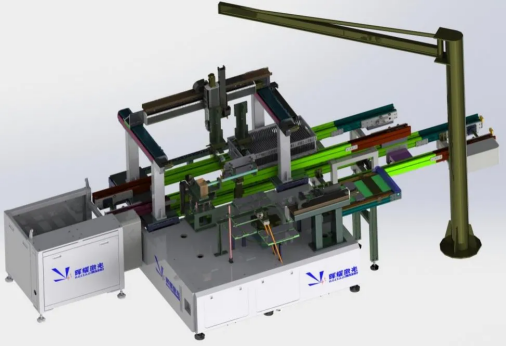

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6