Product

EV Pouch Battery Module PACK Line

- Product description

-

- Commodity name: EV Pouch Battery Module PACK Line

- Commodity ID: 动力软包电池模组PACK线

Automatically sorts and groups pouch cells based on electrical parameters such as voltage, capacity, and internal resistance.

1. Equipment Overview

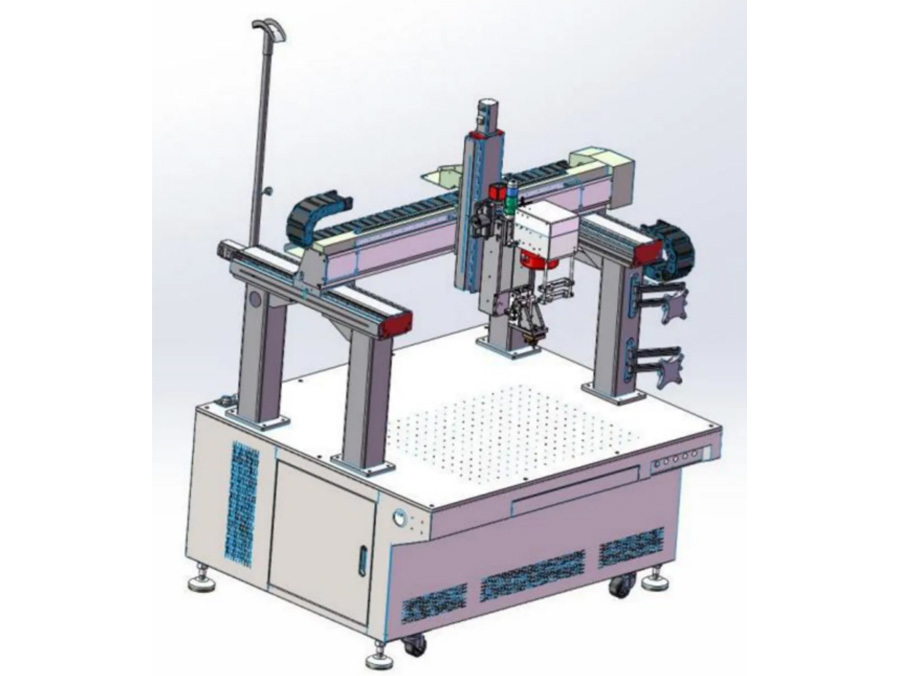

The EV Pouch Battery Module PACK Assembly Line is a fully automated production system designed for assembling pouch cells into battery modules and complete PACKs. It integrates processes such as cell sorting, stacking, welding, cooling system integration, and final testing. The line ensures high precision, consistency, and scalability for electric vehicle battery manufacturing.

2. Key Processes and Modules

2.1 Battery Cell Sorting and Grouping Station

- Function: Automatically sorts and groups pouch cells based on electrical parameters such as voltage, capacity, and internal resistance.

- Specifications:

- Sorting Accuracy: ±0.01% rdg. ±3 dgt (voltage), ±0.5% rdg. ±10 dgt (resistance).

- Sorting Capacity: 600 cells/hour.

2.2 Automatic Cell Stacking Station

- Function: Aligns and stacks pouch cells into precise module configurations.

- Specifications:

- Stacking Method: Robot automatic stacking.

- Alignment Accuracy: ±0.1 mm.

- Stacking Speed: Each cell ≤3 seconds.

2.3 Busbar and Tab Welding Station

- Function: Welds tabs and busbars for electrical interconnection.

- Specifications:

- Welding Type: Fiber laser.

- Welding Accuracy: ±0.05 mm.

- Welding Speed: ≤5 seconds per weld.

- Weld Quality Monitoring: Integrated real-time quality inspection.

2.4 Module Frame Assembly Station

- Function: Assembles pouch cells into a structural frame for mechanical stability.

- Specifications:

- Frame Material: Aluminum or polymer composites.

- Assembly Accuracy: ±0.2 mm.

- Cycle Time: ≤15 seconds per module.

2.5 Thermal Management Integration Station

- Function: Installs cooling plates or liquid cooling systems and applies thermal interface materials (TIM).

- Specifications:

- TIM Application Accuracy: ±0.1 mm.

- Cooling Plate Compatibility: Customizable for liquid or air cooling systems.

- Integration Speed: ≤30 seconds per module.

2.6 Module and PACK Assembly Station

- Function: Assembles multiple modules into a battery PACK, including high-voltage connectors and structural enclosures.

- Specifications:

- PACK Size Range:

- Length: 600–1200 mm.

- Width: 400–800 mm.

- Height: 150–500 mm.

- Assembly Accuracy: ±0.3 mm.

- Cycle Time: ≤120 seconds per PACK.

- PACK Size Range:

2.7 Electrical and Functional Testing Station

- Function: Performs comprehensive electrical, functional, and safety tests on modules and PACKs.

- Specifications:

- Testing Parameters: Voltage, current, internal resistance, insulation resistance, and short-circuit testing.

- Testing Speed: ≤2 minutes per module/PACK.

- Data Logging: Automated data storage for traceability.

2.8 Final PACK Inspection and Quality Control Station

- Function: Conducts visual inspection and quality assurance tests, Including insulation integrity.

- Specifications:

- Inspection Speed: ≤2 minutes per PACK.

3. Production Line Specifications

- Overall Dimensions:

- Length: 65,000 mm.

- Width: 10,000 mm.

- Height: 3,500 mm.

- Weight: Approximately 35,000 kg.

- Production Capacity: Up to 20 PACKs/hour.

- Automation Level: Fully automated with advanced robotics and vision systems.

4. Vision and Quality Inspection Systems

- Alignment Cameras:

- Resolution: 5 MP high-speed cameras.

- Alignment Accuracy: ±0.02 mm.

- Defect Detection: AI-powered algorithms for tab misalignment, welding defects, and frame assembly errors.

- Data Management: Inspection results stored in a centralized database for analysis and traceability.

5. Control and Interface

- Control System: Advanced PLC with distributed control for modular flexibility.

- Human-Machine Interface (HMI):

- 10-inch touchscreen with multi-language options.

- Real-time monitoring and diagnostics.

- IoT and Cloud Integration:

- Remote monitoring, predictive maintenance, and production analytics.

6. Safety Features

- Enclosure Design: Fully enclosed with safety interlocks and emergency stop buttons.

- Laser Safety: Class 1 laser enclosures with certified safety glass.

- Electrical Safety: Overcurrent and short-circuit protection.

7. Electrical Specifications

- Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

- Maximum Power Consumption: 200 kW.

- Control Voltage: 24V DC for auxiliary systems.

8. Cooling System

- Type: Water cooling for welding.

- Cooling Capacity: 80 kW.

- Flow Rate: 30–50 L/min.

9. Environmental Requirements

- Operating Environment:

- Temperature: 15–30°C.

- Humidity: ≤60% RH (non-condensing).

- Noise Level: ≤75 dB during operation.

- Installation Space: Minimum clearance of 2,000 mm around the line.

10. Maintenance and Warranty

- Maintenance Schedule:

- Weekly: Inspect alignment, welding, and cooling systems.

- Monthly: Calibrate vision systems and test stations.

- Quarterly: Comprehensive diagnostics and software updates.

- Warranty Period:

- Standard: 12 months.

- Extended: Available upon request.

11. Technical Parameters

Our EV Pouch Battery Assembly Line is designed for flexibility, accommodating various soft-pack cell dimensions with high-precision handling.

Parameter Specification (Standard / Customizable) Compatible Cell Types VDA 355 / 390 / 590 Modules, Standard Soft Pouch Cells Line Capacity (Throughput) 10 - 20 PPM (Modules Per Minute) / Customizable Yield Rate (FTQ) > 98.5% Welding Technology Ultrasonic Wedge Bonding (For Al/Cu Tabs) Stacking Precision ±0.1 mm (6-Axis Robotic Handling) MES Compatibility Full Traceability (Data storage > 10 years) Environmental Control Optional Dry Room / Clean Room Integration (ISO Class 8) Engineering Note for Pouch Cells:

Soft pouch cells are highly sensitive to dust and humidity during assembly. Unlike our Prismatic Assembly Lines, this Pouch Line is equipped with optional FFU (Fan Filter Units) and specialized Soft-tab Ultrasonic Welding stations to prevent tab damage during the stacking process.

Key words:

Series of Products

The Huiyao Laser Cell OCV Testing & Sorting Machine is a critical component for ensuring the quality and consistency of prismatic battery modules. This semi-automatic station is designed to accurately measure the Open Circuit Voltage (OCV), AC Internal Resistance (ACIR), and polarity of individual cells *before* they enter the main assembly line. By sorting cells into precise groups based on these parameters, it guarantees module balancing, safety, and optimal performance.

The Huiyao Laser Pneumatic Stacking & Pressing Machine is a high-precision, semi-automatic station designed for the flexible assembly of prismatic battery modules. It ensures optimal cell compression and alignment during the manual stacking process, which is critical for module durability, performance, and safety. This unit is ideal for R&D, prototyping, and small-batch production environments where process flexibility and precise pressure control are paramount.

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

undefined