Quality ESS Prismatic Battery Module Pack Assembly Line Supports Energy Storage

Release time:

2025-12-09

The demand for reliable and efficient energy storage systems (ESS) is growing alongside the expansion of renewable energy sources like solar and wind. These systems rely on large-scale battery packs to store and deliver power consistently. The manufacturing process for these critical components directly impacts their performance, safety, and lifespan. For companies producing these systems, the implementation of a well-designed production line is a significant step, and many are evaluating the benefits offered by a dedicated quality ESS prismatic battery module pack assembly line.

The demand for reliable and efficient energy storage systems (ESS) is growing alongside the expansion of renewable energy sources like solar and wind. These systems rely on large-scale battery packs to store and deliver power consistently. The manufacturing process for these critical components directly impacts their performance, safety, and lifespan. For companies producing these systems, the implementation of a well-designed production line is a significant step, and many are evaluating the benefits offered by a dedicated quality ESS prismatic battery module pack assembly line.

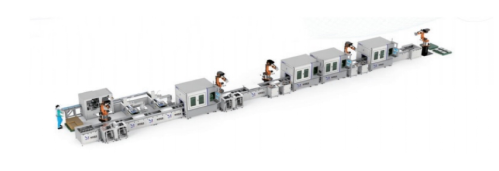

Unlike lines built for cylindrical cells, an assembly line optimized for prismatic cells must handle their distinct rectangular form factor. This requires precise automation for cell handling, stacking, and busbar integration. For a production engineer, the advantage of a high-throughput automated system is clear: it ensures consistent module assembly, minimizes human error, and maintains the stringent alignment tolerances necessary for optimal thermal management and electrical performance within the pack.

The integration of inline quality assurance is particularly vital for energy storage applications. Modules destined for commercial or grid-scale ESS must operate reliably for years under continuous charge-discharge cycles. A robust quality ESS prismatic battery module pack assembly line would incorporate automated testing at stages like busbar welding and module insulation, ensuring each unit meets specifications before final pack integration. This focus on traceability and precision during manufacturing helps build the foundational reliability required for large-scale energy storage solutions, supporting a more stable and sustainable power infrastructure.

key word:

quality ESS prismatic battery module pack assembly line