What is 3D Printing?

Release time:

2025-06-25

3D printing, also known as additive manufacturing, is a process of building three-dimensional objects layer by layer from digital models. Unlike traditional subtractive manufacturing methods (e.g., milling or turning), 3D printing allows "what you design is what you get," drastically expanding the possibilities of product design and production. Today, it is not just a forming technique, but a core driver of industrial transformation and innovation.

3D printing, also known as additive manufacturing, is a process of building three-dimensional objects layer by layer from digital models. Unlike traditional subtractive manufacturing methods (e.g., milling or turning), 3D printing allows "what you design is what you get," drastically expanding the possibilities of product design and production. Today, it is not just a forming technique, but a core driver of industrial transformation and innovation.

Features of Industrial 3D Printing

1.Metal 3D Printing: A Breakthrough for Advanced Manufacturing

Lightweight design: Aerospace parts weight reduced by over 40%

Part consolidation: GE fuel nozzle reduced from 20 parts to just 1

Precision custom manufacturing: Medical implants match rate of 99.7%

Cost revolution: Monolithic defense alloys, 60% cost savings for turbine blade repair

2.Non-metal 3D Printing: An Accelerator for Flexible Manufacturing

Rapid prototyping: Auto R&D cycles reduced by 70%

Functional elastomers: Wearables, soft robotics

Low-cost customization: Near-zero marginal cost for personalized electronics

Complex geometry creation: Curved architectural molds in under 24 hours

Applications of 3D Printing

Aerospace: Lightweight structures, engine parts, heat exchangers

Medical: Orthopedic implants, dental guides, surgical templates

Automotive: Engine prototypes, custom enclosures, drive components

Education & R&D: Lab devices, teaching models

Architecture & Art: Concrete molds, parametric installations

How to Select a 3D Printing System?

●Material compatibility: Can the system handle required metals or engineering polymers?

●Precision & size: Does it meet the detail and build size needs?

●Software & intelligence: Includes smart monitoring, closed-loop control, and defect prediction?

●Scalability & maintenance: Modular design, quick swap parts, and remote support?

●Cost & delivery: Total cost of ownership including materials, service, and lead time

Supplier of Industrial 3D Printing: Huiyao Laser

Huiyao Laser (Luoyang) Technology Co., Ltd. is a high-tech enterprise specializing in laser-based intelligent manufacturing solutions. With advanced additive manufacturing systems, we empower industries to overcome traditional constraints and enter a new era of digital fabrication.

Our Core Advantages:

Dual-material platform: Metals (e.g., titanium, tool steel); Non-metals (e.g., plastics, ceramics)

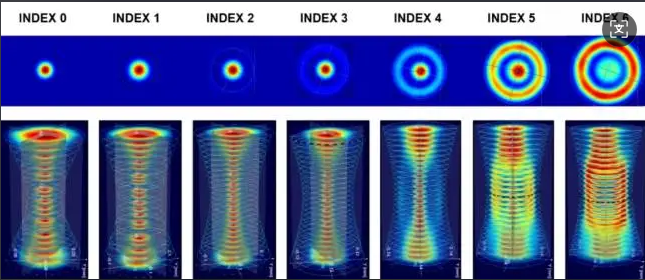

Intelligent closed-loop system: Real-time melt pool monitoring + AI defect warning

Distributed management: Remote monitoring & cloud-based task scheduling

Open material ecosystem: Third-party material compatibility, 45% cost savings

Modular scalable design: From R&D to full-scale production with ease

Empowering Boundless Innovation – Huiyao Laser, Your Trusted 3D Printing Partner.

key word: