Solution

Laser Welding

- Product description

-

- Commodity name: Laser Welding

- Commodity ID: 激光焊接

Laser welding uses focused laser beams to join materials with precision and speed.

The Power of Laser Welding

Laser welding uses focused laser beams to join materials with precision and speed. Compared to traditional welding methods, laser welding offers several advantages:

- High Precision: Achieves micron-level accuracy, crucial for intricate components.

- Strong Joints: Produces high-quality welds with minimal defects.

- Speed and Efficiency: Significantly faster processing times compared to conventional techniques.

- Versatility: Suitable for various materials, including steel, aluminum, copper, and even dissimilar metals.

- Minimal Heat Distortion: Concentrated heat reduces the risk of warping or damage to surrounding areas.

Huiyao Laser Technology: Enabling the Future of Manufacturing

Huiyao Laser Technology has developed a wide range of laser welding solutions that cater to industries such as automotive, energy storage, aerospace, consumer electronics, and medical devices. Here's how Huiyao's innovative systems are redefining laser welding applications:

1. Automotive Manufacturing

- Battery Welding: Huiyao laser systems are widely used in welding battery components such as tabs, modules, and PACKs for electric vehicles (EVs). Precision welding ensures the durability and reliability of battery connections.

- Chassis and Body Assembly: Laser welding delivers strong and lightweight joints for vehicle frames, improving fuel efficiency and safety.

- Exhaust Systems: Handles high-strength steels and alloys to ensure leak-free and durable exhaust assemblies.

2. Energy Storage Systems (ESS)

- Battery Modules and PACKs: Huiyao’s technology excels in joining prismatic and cylindrical battery components, meeting the growing demand for renewable energy storage solutions.

- High-Performance Connections: Laser welding enhances the electrical and thermal performance of ESS systems.

3. Aerospace Industry

- Lightweight Material Welding: Ensures reliable joints for aluminum and titanium components critical for aircraft structures.

- Precision Repair: Enables localized repairs on turbine blades and other aerospace parts without compromising integrity.

4. Consumer Electronics

- Miniature Components: Ideal for welding tiny parts in smartphones, wearables, and other electronics where precision is paramount.

- Aesthetic Finishes: Delivers clean welds without post-processing, maintaining the sleek appearance of consumer products.

5. Medical Devices

- Biocompatible Welding: Suitable for joining stainless steel, titanium, and other biocompatible materials used in surgical tools and implants.

- Hermetic Sealing: Ensures leak-proof sealing of medical sensors and devices.

Why Choose Huiyao Laser Technology?

1. Tailored Solutions

Huiyao Laser specializes in customizing systems to meet specific manufacturing requirements. From EV battery assembly to aerospace part fabrication, each solution is optimized for precision and productivity.

2. Cutting-Edge Technology

With continuous innovation, Huiyao’s laser systems incorporate features like:

- Real-Time Monitoring: Ensures consistent weld quality.

- AI Integration: Optimizes process parameters for improved efficiency.

- Advanced Cooling Systems: Extends machine life and ensures reliability.

3. Industry Expertise

Huiyao has a proven track record of successfully implementing laser welding solutions across diverse industries, delivering significant cost savings and performance enhancements.

4. Commitment to Sustainability

Laser welding aligns with global sustainability goals by reducing material waste and energy consumption. Huiyao Laser takes it further by designing eco-friendly systems that minimize environmental impact.

Driving Innovation Across Industries

Huiyao Laser Technology is not just a provider of laser welding equipment but a partner in innovation. By enabling precision manufacturing and addressing industry challenges, Huiyao empowers companies to stay ahead in a competitive market.

Whether you're looking to enhance production efficiency, improve product quality, or adopt sustainable manufacturing practices, Huiyao Laser Technology offers the tools and expertise to make it happen.

Explore the Future with Huiyao Laser Technology

Ready to transform your manufacturing processes? Contact Huiyao Laser today to learn more about how our laser welding solutions can benefit your industry. Together, we can create a future defined by precision, efficiency, and sustainability.

Key words:

Laser Welding

Series of Products

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

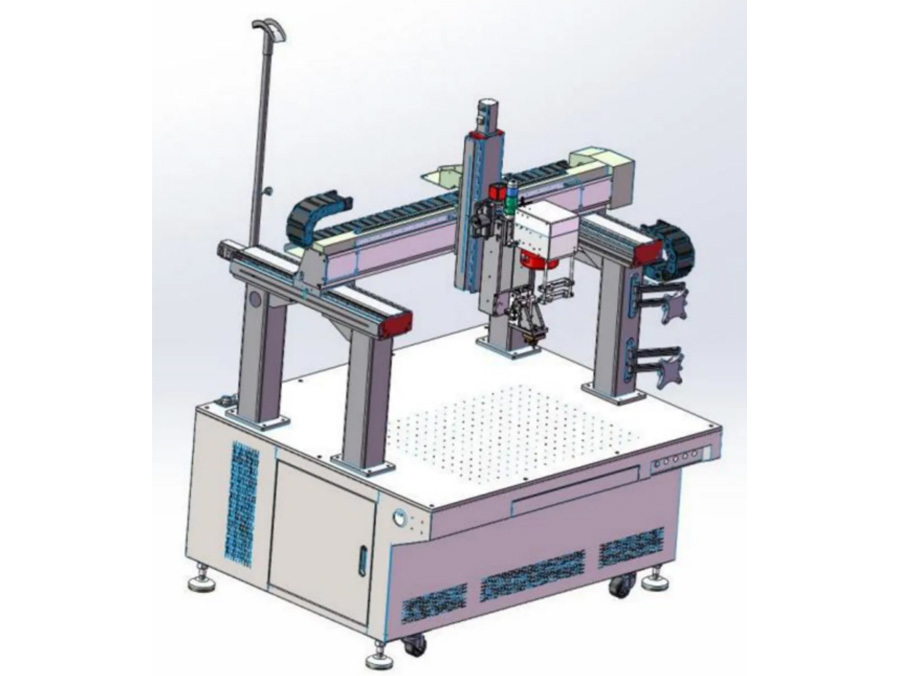

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

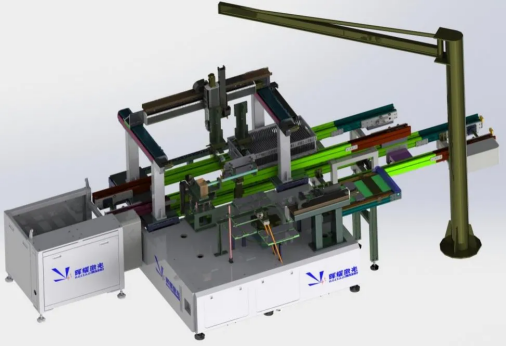

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

FAQ

Q

How do you ensure consistent weld quality in the assembly of Prismatic battery packs?

A

Q

What are the best practices for cell alignment and stacking in a Prismatic battery PACK assembly?

A

Copyright © Huiyao Laser Technology (Luoyang) Co., Ltd. Has supported ipv6