Turnkey Battery Production Line & Laser Welding Solutions

Relying on the support of Dalian University of Technology Luoyang Research Institute and other scientific research institutions, the company has built up a skilled R&D team, which is committed to providing customers with a comprehensive range of high-end new energy intelligent equipment such as Battery Cell Assembly Line, Battery Structural Parts, Battery Module Automation Line , Battery PACK Automation Line and CCS Intelligent Manufacturing Production Line

Huiyao Laser is a leading battery laser welding machine manufacturer offering professional battery pack and battery module welding solutions for many fields, such as energy storage systems of research and development machines, as well as complete assembly lines for module and battery pack production.

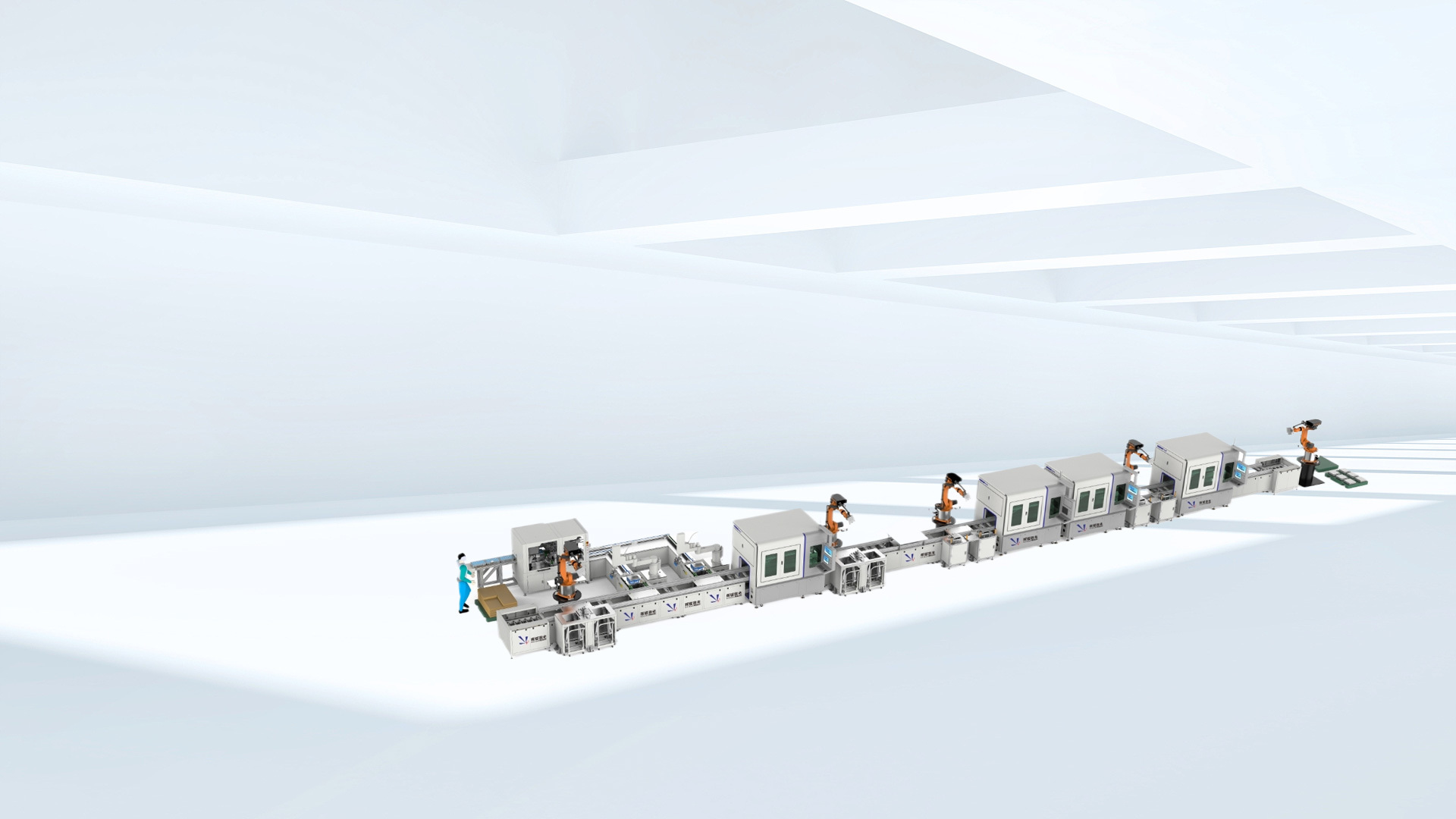

Huiyao Laser Fully-Automated Energy Storage Prismatic Battery Module PACK Line

Huiyao Laser Energy Storage Automatic Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

Huiyao Laser Semi-Automated Energy Storage Prismatic Battery Module PACK Line

The Huiyao Laser Energy Storage Prismatic Battery Module PACK Line is an efficient, intelligent and customized automated production line, specifically designed for the energy storage field. It is suitable for application scenarios such as large - scale energy storage systems, home energy storage, and industrial energy storage. This production line integrates advanced laser welding technology, automated assembly systems, and intelligent detection equipment, aiming to provide customers with the production of battery modules with high consistency and high reliability.

As industries continue to evolve towards greater precision and efficiency, laser cutting has become a game-changer in manufacturing processes.

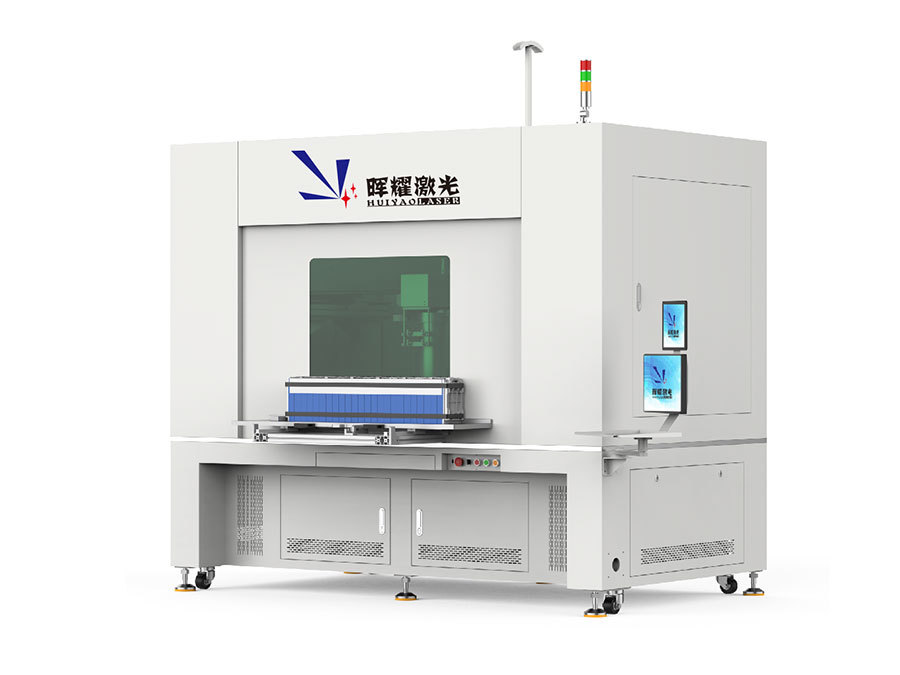

Battery Top Cap Welding Equipment

Precise welding of top caps onto battery cases, ensuring airtight sealing and electrical connectivity for prismatic and pouch batteries.

EV Pouch Battery Module PACK Line

Automatically sorts and groups pouch cells based on electrical parameters such as voltage, capacity, and internal resistance.

Dual-Station Enclosed Rotary Welding Machine

Precision welding of battery components, metal parts, or other materials requiring high-speed, dual-station rotary processing. The enclosed design ensures operator safety and minimizes environmental interference.

EV Prismatic Battery CTP Automatic Welding Line

The EV Prismatic Battery CTP (Cell-to-Pack) Automatic Welding Line is a high-performance.

Comprehensive Pouch Battery Module PACK Automatic Production Line for Efficient Output 12PPM is designed for the modular production of solid-state batteries, featuring high automation, flexibility, and integrated quality control (QC) systems. It ensures efficient production while maintaining strict quality standards. The line is suitable for electric vehicles, energy storage systems, consumer electronics, and more, supporting the production of various specifications of solid-state battery modules.

In an era of increasing demand for efficiency, precision, and sustainability, laser cleaning has emerged as a revolutionary solution for industrial surface preparation and restoration.

Automatic Explosion-Proof Valve Welding Machine

Specialized in precise laser welding of explosion-proof valves for prismatic and cylindrical batteries, ensuring a robust and airtight weld to meet high safety standards.

ESS Prismatic Battery Module PACK Assembly Line

The ESS Prismatic Battery Module PACK Assembly Line is engineered to deliver high-precision, high-throughput manufacturing of energy storage system (ESS) prismatic battery packs.

Solution

Huiyao Laser is always committed to innovation and R&D. With our strong R&D team and advanced production facilities, we continue to push forward the advancement of laser technology and the expansion of application areas.

Battery Production Lines

PRODUCT

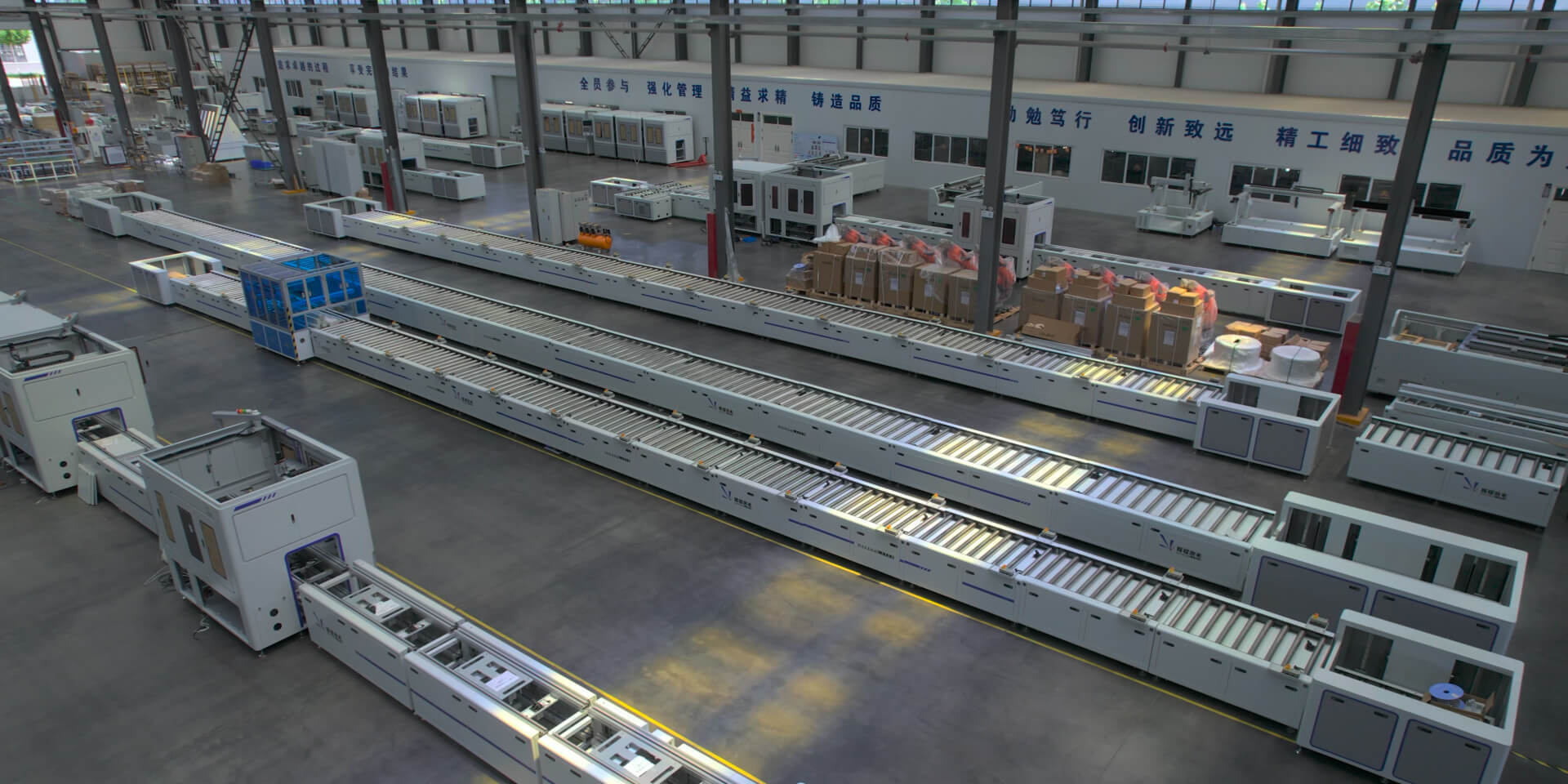

Smart Factory Systems

PRODUCT

About Huiyao Laser

Huiyao Laser Technology (Luoyang) Co., Ltd. is a leading provider of intelligent equipment for the new energy industry. Integrating advanced laser processing and automation, we deliver customized solutions for battery module and PACK lines, ESS assembly, and high-end laser/additive manufacturing. With strong R&D and “Science and Technology Deputy GM” collaborations, we ensure innovation, quality, and lifelong service to drive global intelligent manufacturing.

Our certification

The company was founded in

The company occupies an area of

Serving countries and regions worldwide

Technological innovation drives the future

Since its establishment, Huiyao Laser has established in-depth cooperation with famous domestic and foreign enterprises, such as CALB(China Aviation Lithium Battery), BYD, SVOLT Energy, State Energy Group, XujiGroup, Sacred Sun Power, Tianhui Lithium Battery, New Taihang, Harbin Coslight, and Wan Yang Lithium Battery, etc. The company covers an area of 10,800 square meters and has a team of skilled researchers and developers.

View more +Quality Advantage

with a number of automated and semi-automated production lines and advanced processing equipment, and ISO9001 quality management system certification, ISO14001 environmental management system and ISO45001 occupational health and safety management, and has obtained a number of utility model patents and soft-authored patents.

Industry Applications

Huiyao Laser's equipment and production lines are widely used in many industries such as automotive, electronics, aviation, etc. Huiyao Laser's equipment and production lines are well known for its high speed, high precision, high stability and high reliability, and are widely recognized and applied worldwide.

Customized solutions

Huiyao Laser also provides a full range of pre-sales consultation and after-sales service.The team consists of experienced engineers and technologists who are able to provide customized solutions according to customers' needs, as well as training and support to ensure that customers are able to utilize their equipment to its full potential.

Sustainable development

Our mission is to create value for our customers, promote the development of the industry and contribute to the realization of sustainable development through the innovation and application of laser technology. Huiyao Laser warmly welcomes partners from all walks of life to contact us and explore the unlimited potentials and business opportunities of laser technology.

Win win cooperation

The choice of brand trust

Since its establishment, Huiyao Laser has established in-depth cooperation with famous domestic and foreign enterprises, such as CALB(China Aviation Lithium Battery), BYD, SVOLT Energy, State Energy Group, XujiGroup, Sacred Sun Power, Tianhui Lithium Battery, New Taihang, Harbin Coslight, and Wan Yang Lithium Battery, etc.

Committed to providing innovative battery module PACK customized production line comprehensive solutions for various industries

If you have any needs, please call the national unified service hotline

News

For more information about Huiyao Laser, please visit our official website or contact our sales team.We look forward to working with you and providing you with excellent laser solutions.

Essential Insights on Lithium Battery Testing Equipment for Professionals

2026-02-06

Al-Cu Busbar Laser Welding: Managing IMC for ESS (2026)

2026-02-06

The Benefits of Laser Welding Machines for Small Enterprises

2026-02-04

Best Battery Cell Sorting: OCV/IR Precision Standards (2026)

2026-02-04

Understanding Lithium Battery Pack Assembly: Key Insights for Professionals

2026-02-02

CCD Real-time Weld Monitoring System 2026

2026-02-02

Improving Production Speed with Laser Cutting Technology: A Comprehensive Guide

2026-01-31

12 PPM Prismatic ESS Module & PACK Line: 2026 Technical Upgrades

2026-01-30

The Essential Guide to Laser Marking in the Optical Components Industry

2026-01-29

Battery Pack EOL Testing Checklist: Safety & Efficiency Standards 2026

2026-01-29

Battery Pack Assembly Process: A Step-by-Step Engineering Guide (2026)

2026-01-28

Prismatic Cell Blue Film Wrapping: Solving the Bubble & Wrinkle Challenge

2026-01-26